Innovative coatings to extend aircraft life

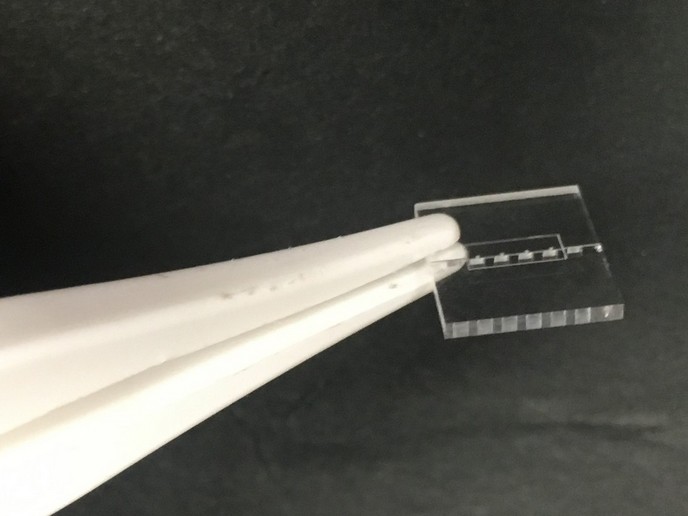

In the cold spray deposition method, powder particles are accelerated to supersonic speeds in a jet of gas (helium) at temperatures well below their melting point. Within COLA(opens in new window) (Coaxially laser assisted cold spray), researchers used a variant of the cold spray technique that eliminates use of helium, which is costly. The method involved use of laser irradiation that makes the surface softer, thereby greatly facilitating particle deposition. The team developed two prototypes consisting of omnidirectional spray heads with a ring array of diode lasers that can be retrofitted around different commercial cold spray systems. The lasers were coaxially arranged around bespoke, process-optimised, interchangeable powder delivery nozzles. User-controlled elements provided tailored beam shapes to heat substrates. In addition, a built-in substrate temperature control concept with multiple axially arranged thermal sensors enabled scientists to control surface temperature. Both laser-assisted cold spray systems produced high-quality dense coatings, preventing component oxidation and stress corrosion cracking. Eliminating use of helium and using nitrogen gas instead made the COLA process more affordable. Compared to other processes, the laser-assisted cold spray deposition process also offered higher deposition rates. In particular, laser irradiation made nickel and copper alloy deposition four times more efficient than the conventional cold spray process. It also decreased porosity content down to 0.1 %, kept oxygen content below 0.2 % and produced coatings with hardness values 80 % higher than the substrates. Lower-weight and more cost-efficient bronze-coated steel parts can find use in a vast array of industries. These include the chemical, water desalination, naval architecture, power generation, transport, building, and iron- or steelmaking industries. Nickel-alloy coated steels are necessary for applications requiring either a high degree of corrosion resistance such as in battery and automotive components or ductile/low-stress repairs such as iron casting. Regarding aircraft, the newly developed process should result in improved aeroengine components with long predicted service lives to ensure air passenger safety. Except for nickel and copper, the COLA process also holds great promise for use with other materials.