Modelling of damage and cracking processes

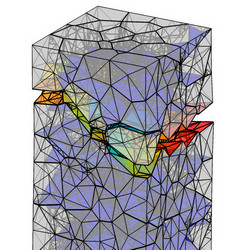

Polycrystalline materials composed of aggregates of crystals or grains of varying size and orientation exhibit complex fracture behaviours difficult to capture with single-scale models. Understanding these behaviours is important to facilitate the development of lighter and more reliable transport structures that positively impact emissions, costs and safety. Scientists exploited a novel cohesive grain boundary integral formulation to link information at different scales with EU-funding of the MULTISCALE MODEL project. It seamlessly accounts for the way that micro-scale features affect the macro-continuum response which, in turn, affects micro-state evolution during initiation and propagation of cracks. The grain-level model based on the cohesive-frictional grain boundary formulation accounts for the progressive intergranular degradation and failure of polycrystalline materials at the micro-scale. Computational results have been successfully compared to available data. This micro-scale model was integrated into the multi-scale model in which the macro-scale is described with a classical boundary element formulation. A material homogenisation procedure predicts the damage at the macro-scale resulting from the progressive intergranular failure of the microstructure. MULTISCALE MODEL results have been presented at several international conferences and in several publications in peer-reviewed scientific journals. Fracture propagation predictions are still largely based on semi-empirical assumptions. More accurate modelling of the mechanisms of brittle failure in polycrystalline materials will have important impact on the EU aerospace and automotive sectors. In addition to enhancing current engineering and maintenance practices, these results also strengthen the EU position in the in the growing field of multi-scale modelling.