Smart robotics and automation marketplace: unleashing human potential with augmented human-machine teamwork

The future of manufacturing lies in smart, connected factories where humans and machines work together, recognising the invaluable contributions of skilled workers while leveraging the efficiencies and precision of digital technologies. By integrating human labour with automated processes, companies can increase productivity, flexibility and worker satisfaction, ultimately driving innovation and competitiveness in the manufacturing sector. Coordinated by the Technical University of Munich(opens in new window), the EU-funded SHOP4CF(opens in new window) project created a marketplace of technologies and tools to usher in a new era of human-centred robotics(opens in new window) in Europe.

Supporting humans in production activities

SHOP4CF’s 25 user-friendly plug-and-play components for robotics and automation are available on the Robotics and Automation Marketplace(opens in new window). They leverage emerging technologies including augmented reality, virtual reality, digital twins, machine learning, deep learning, process automation, robotics and IoT. The common architecture is based on RAMI 4.0 a reference architectural model designed to provide a common language and framework for Industry 4.0 applications, and FIWARE Open Source products and services that support the digital transformation. This makes them easy to install and use. According to Jesus Tapia, Head of the IMPACT Accelerator(opens in new window) of ISDI(opens in new window): “Expectations of corporations evaluating components in the marketplace go beyond an individual component’s capabilities. If someone interested in a component does not find helpful guidance, the rate of adoption is significantly decreased.” Those interested in SHOP4CF’s components, and their use will find 13 open online courses covering topics including ethics, data, predictive maintenance and even funding. “Training is the lever that will boost adoption,” adds Tapia.

Creating a bridge between large corporations and developers

SHOP4CF’s team of 20 partners – including large corporations, SMEs, and research and university partners – made contributions beyond the development of technological solutions. The consortium supported ‘experiments’ selected for an 8-month mentoring programme and four large corporate partners tested the developed solutions. “The involvement of large, internationally known corporations has been key to fostering excitement within the SHOP4CF community. Furthermore, there has been a win-win for the parties involved in the use cases: large corporations have experimented with a new solution at very low cost and risk, and developers of components have had great exposure to these large corporations,” explains Tapia.

Showcasing the benefits in world-class factories

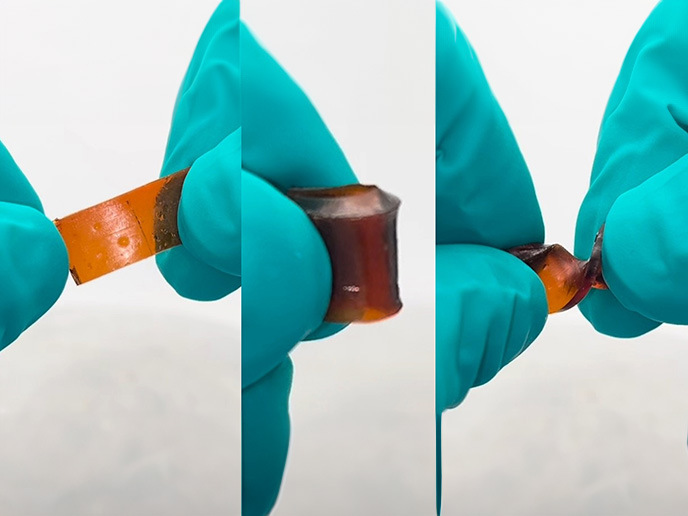

Four global manufacturers applied some of SHOP4CF’s components, enabling them to address real challenges. Siemens improved automatic data acquisition, storage and traceability with user-friendly interfaces, and also increased human safety. Automated guided vehicles and digital reality applications supported non-expert workers in properly placing electronic components on printed circuit boards at the Bosch factory in Madrid. SHOP4CF’s components supported Volkswagen in reducing body paint defects by predicting and managing maintenance on a key machine whose faulty performance impacts paint adhesion. Finally, at Arçelik, with plants in multiple countries, a team of engineering experts at headquarters remotely supported the local factories in inspection and maintenance through augmented reality and virtual reality. “We now have real examples where robots and AI can support – not replace – humans, unleashing human potential. By taking over monotonous and repetitive tasks with low added value, the tools let people use their machine-superior talents more effectively. As more and more components are added, more use cases can be solved and more large organisations will be attracted. SHOP4CF has real potential to snowball, transforming European manufacturing with plug-and-play components for robotics and automation,” Tapia concludes.