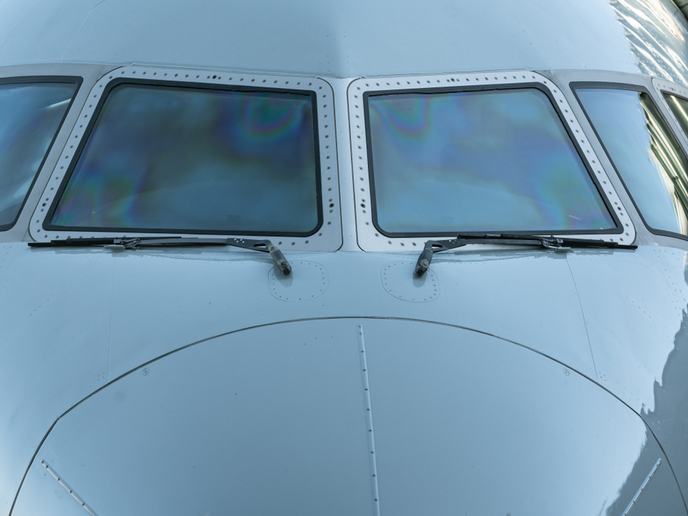

Aerospace goes with natural laminar flow

The Breakthrough Laminar Aircraft Demonstrator in Europe (BLADE) is part of Clean Sky's Smart Fixed Wing Aircraft (SFWA) programme. This ambitious EU-funded multi-partner research activity aims to reduce the environmental footprint of air transport. By reducing aircraft drag and noise, SFWA will make a critical contribution to achieving the Single European Sky initiative's environmental objectives. Within the project NLFFD (NLF starboard leading edge & top cover design & manufacturing trials), researchers developed leading edge assemblies and the upper cover for an NLF wing of the flight test aircraft. Both structures offer NLF levels of performance thanks to new design concepts and manufacturing technologies that deliver ultra-high tolerances and exceptional surface finish. The biggest challenge with designing and manufacturing an NLF wing arises from the need to tightly control the wing surface. Specifically, it is vital to eliminate features such as steps, gaps, roughness and fastener heads because all these lead to turbulent flow. In addition to achieving adequate levels of laminar flow, researchers aimed to use a high-quality design that is suitable for massive production. NLFFD partners produced integrated, co-cured composite upper covers and high-tolerance leading edge assemblies using the same design and development process applied in commercial aircraft components. As a result, the 4.5-m-long by 1-m-wide wing section is of such high quality that it has been considered for flight tests on a modified Airbus A340-300. The innovative wing section is made up of a sandwich panel incorporating polyetheretherketone-based electrothermal ice protection technology with an integrated erosion shield. And even though the NLFFD team had experience in leading edge erosion shields, a whole technology programme was initiated to bolt on a nickel-steel erosion shield. With fewer titanium ribs than a conventional leading edge, the design also includes a foam sandwich in the skin to maintain stiffness. The design requirements of NLF are extremely tight when it comes to undulations of the wing surface under loading. Achieving a flow over the wing's skin supported by fewer ribs but that is sufficiently stiff was a significant part of the researchers' work. During the flight tests, scheduled to take place in 2017, the NLFFD wing section will be used to evaluate the performance of the proposed NLF wing architecture, helping to confirm theoretically predicted environmental benefits. NLF is expected to reduce wing drag by up to 8 % and fuel consumption by about 5 %.