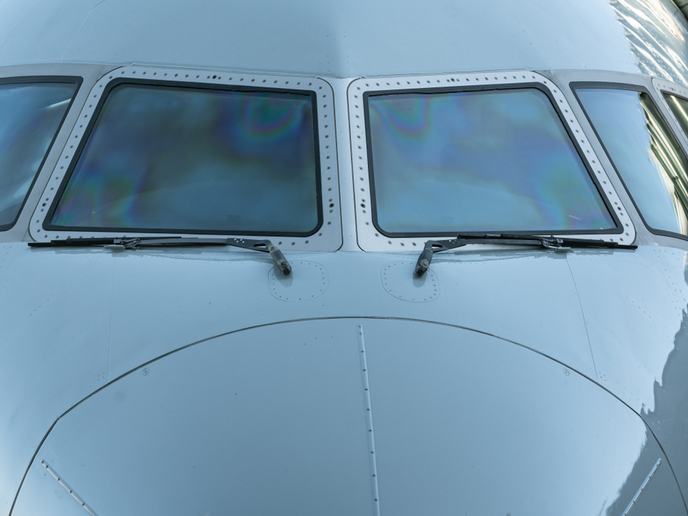

Hydrophobic aircraft windscreen coating advances to next phase

Aircraft windscreen wipers are simple and reliable. However, they add drag. This increases fuel consumption and restricts the wipers’ use to the low speeds of landing and take-off. During high-speed flight, wipers are not used, regardless of weather. So the aircraft carries around extra weight most of the time. Wipers also eventually abrade the windscreens’ surface. Chemical water-repelling coatings have been tried. They were already a little unclear, but scratches from rain, hail and dust made that worse.

Windscreen coating for next-gen aircraft

The EU-funded HaSU(opens in new window) project developed a durable new hydrophobic (water-repelling) coating for the NextGeneration Civil Tiltrotor(opens in new window) (NextGenCTR) aircraft. This aircraft is a bus-sized passenger model able to take off and land vertically without needing airports. The NextGenCTR is being developed by the EU’s Clean Sky(opens in new window) umbrella programme, of which HaSU is also a member. HaSU’s hydrophobic coating keeps the NextGenCTR windscreen clear of water and ice, eliminates the extra weight of wiper mechanisms, and addresses the problems affecting previous generations of coatings. “Our new coating is a sol-gel, composed of polyurethane silanes subjected to hydrolysis,” explains project coordinator, Ernesto Benini. The coating is essentially painted onto the windscreen, where it dries. This creates a hard layer, which easily sheds rainwater, on the outside of the windscreen. In addition, the coating includes a transparent, heat-conducting layer applied to the glass surface. This facilitates ice removal.

Testing shows promise

During six months of extensive environmental testing, the coating showed no substantial degradation. This alone is significant compared to previous coatings. How long it will last is unknown for the present, but it could be much longer than six months. Even so, the final product will probably need periodic reapplication, under controlled conditions to ensure consistency. Each windscreen will be removed from the aircraft and sent to the factory for reapplication of the coating. This will take a couple of hours, which Benini states is a very competitive and efficient process. Project researchers did not test the coating’s resistance to impact strikes. “However, we believe that this coating is resilient enough to withstand impacts,” reports Benini. “Most of the resistance is guaranteed by the underlying multilayered structure, which has been designed to take the pressure of bird strikes, hail and similar impacts.” Researchers developed the technology from technology readiness level(opens in new window) TRL 4 to TRL 6. So the technology has been tested in its intended environment, and shown to be feasible. For the immediate future, the team will be refining the manufacturing process and maturing the technology. From there, the pathways to airworthiness accreditation and full commercial readiness will be relatively straightforward. Although specifically designed for the NextGenCTR, the new coating should be transferrable to many other types of vehicle, including trains and cars. Aircraft operators will be among the first beneficiaries. The new coating will remove weight and drag, making aircraft cheaper to operate. Pilots will also appreciate the improved and long-lasting visibility compared to earlier coatings.