Studying industrial catalysts

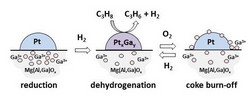

Platinum-based catalysts are used for a wide variety of industrial processes involving hydrocarbons. Unfortunately, the efficiency of these catalysts is affected by the build-up of unwanted carbon deposits known as coke. The EU-funded 'Intrinsic catalytic kinetics analysed and reconciled with industrial conditions' (ICKARUS) project aimed to study the behaviour of novel platinum (Pt) catalysts during the propane dehydrogenation reaction process. Project members studied Pt nanoparticle catalysts promoted by gallium, tin or indium atoms. These were shown previously to have improved resistance to coking (build-up of a type of carbon), making them ideal subjects for further study and exploitation. Researchers also found that bi-metallic catalysts had better overall catalytic performance due to certain active sites being blocked by carbon deposits. They also improved understanding of how alloys form on the catalyst surface under certain conditions. Lastly, ICKARUS deployed a Temporal Analysis of Products instrument, using it to study the catalysis of propane dehydrogenation. This is a technique that measures a range of physical characteristics of a reaction process. These insights will inform innovations geared towards improving industrial catalysis, thus helping to boost global industry.