Better flame-retardant plastics

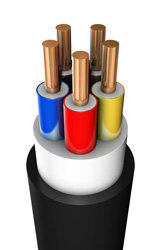

Cost-effective and high-performance PP is highly flammable yet difficult to protect against fire. Conventional halogenated flame retardants (treated with chemicals in the halogen group, including bromine) serve their designated function well without affecting polymer properties. However, they release toxic and corrosive smoke when heated excessively. Currently available halogen-free products, while effective against fire, require high loadings that have a detrimental effect on polymer properties. Mixed intumescent polymeric salts (MIPS) are an inexpensive yet high-performance alternative. Intumescent chemical systems expand into thick insulating chars when exposed to high temperatures. They provide protection to underlying systems both through endothermal chemical reactions (that absorb heat) and by providing a physical barrier to heat transfer. Scientists have advanced the state of MIPS for PP fire protection through work on the project PP-MIPS(opens in new window). They focused on two high-performance applications that are currently only possible using halogenated polymers. These were PP fibres meeting protective clothing standards and PP cable insulation jackets achieving the strictest international performance standards. MIPS chemistry based on easily synthesised phosphorous-rich compounds combines the essential reaction components in a single molecule one step away from intumescence. Scientists focused on formulations with higher activation temperature and greater resistance to decomposition. Work included scaling up production of MIPS to supply the quantities needed for testing. Investigators also conducted numerous processing trials to assess whether or not the MIPS affected polymer processing capabilities or mechanical properties of components. The vast amount of knowledge accumulated within the scope of the PP-MIPS project has brought eco-friendly fire protection for PP to a mature stage for final optimisation. The rival to conventional halogenated plastics is sure to make a splash given the pressing need to find a replacement fulfilling stricter regulations.