Ensuring reliably high quality

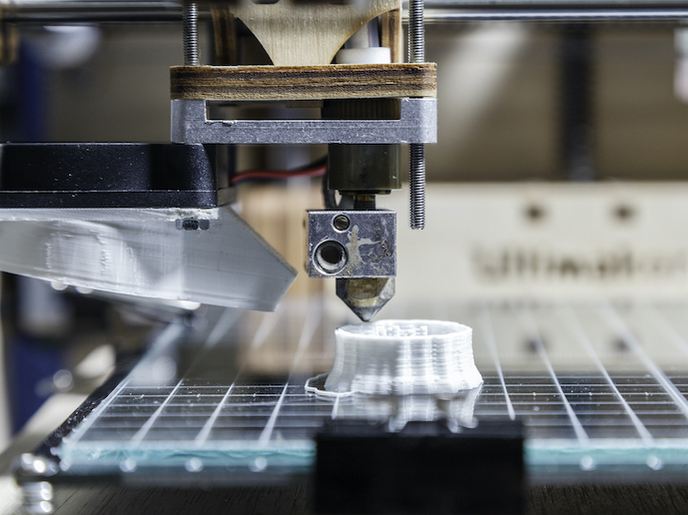

AM, a bottom-up approach of layering materials according to a computer-aided design, or CAD, file specification, has proved itself a valuable ally in many industries. Standardisation is imperative in every field, whether in terms of manufacturing or testing methods, measurement techniques, data formats or quality indicators. The EU-funded project 'Support action for standardisation in additive manufacturing' (SASAM)(opens in new window) has created a Standardisation Roadmap document open to the AM community for review and is available on the project website. Finalisation with user input and subsequent implementation will encourage widespread uptake that will drive the field forward. SASAM's Roadmap is intended as a template for development of a European standard. It elucidates the importance of standardisation for industrial acceptance and existing AM standards. It also identifies gaps in standardisation and prioritises a list of standards that will facilitate industrial compliance with best practices. Liaising with major norming or standardisation institutes as a regular component of AM platform meetings will ensure goals are met. AM is an efficient and effective way to produce high-quality parts with complex geometries. In fact, it has made possible the production of forms long considered unattainable. In addition, it minimises much of the tooling and machinery required by other manufacturing processes and with it the associated scrap, electricity consumption and excessive setup. However, AM has been largely focused on prototyping activities that, by their nature, do not lend themselves to repetitive tasks that can be standardised. Further, even for larger production batches, the process parameters intricately affect product quality. Lack of standardisation results in unacceptable variations, particularly for the requirements of aerospace and biomedical applications. AM technologies will support innovation and cost- and resource-effective production for a highly competitive EU manufacturing sector. The Strategic Research Agenda drafted by the European Platform for AM highlights standardisation as a key pillar of that contribution and SASAM has addressed it admirably.