Materials and processes for strain sensors

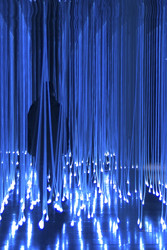

Optical fibres are transparent and flexible cables made of hollow glass (silica) or plastic (polymer) with very thin diameter. They are used in numerous medical and industrial applications, including communications and sensing. Polymer optical cables have lower cost and higher flexibility compared to silica. This, together with their ability to sense much higher strains than silica, makes them particularly useful in fibre Bragg grating (FBG) sensors. FBG sensors have perturbations in their refractive indices in their cores that manipulate light in useful ways for measuring strain. EU support of the project 'Polymer grating sensors' (POGS) enabled scientists to push the frontiers of the field, improving the technology behind POF gratings for sensor applications. Modelling and development work that focused on micro-structured POFs (mPOFs) led to fabrication of a fibre for grating sensor inscription used throughout the project. It was the first instance of an mPOF doped with benzyl dimethyl ketal (BDK). Inscription was made possible by creating a new advanced facility with numerous advantages. It scanned the POF horizontally with an ultraviolet (UV) laser rather than vertically through a phase mask to make the structural perturbations. This enabled easy alignment, longer grating lengths and many other benefits. Gratings inscribed in mPOFs doped with BDK produced unusually high UV photosensitivity, facilitating a reflectivity of 99 % after only 13 minutes of radiation. Results were published in a peer-reviewed scientific journal. Assessment of the long-term stability of the fabricated gratings yielded novel results and insights leading to another publication. Finally, cleaving the POF is much more difficult than cleaving silica due to its viscoelasticity. Previously, it required expensive electronics and controllers, making the setup expensive and difficult to move. POGS developed a novel methodology, significantly enhancing portability and approaching the simplicity of a silica optical fibre cleaver. The setup also avoids the need to polish the cable's ends in order to connect it to other equipment. The project has significantly enhanced understanding of the inscription process to make highly sensitive FBG sensors while providing a practical technique for cleaving the fabricated cables. Negotiations are underway for commercialisation of the technology.