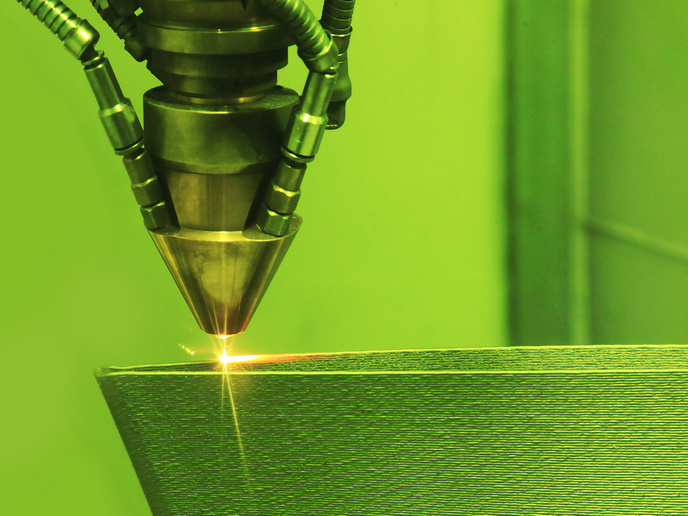

Laser technology for reliable plastic-metal joints

In a continuing effort to reduce energy consumption, the automotive industry is increasingly looking at plastics or composites to replace the heavier metal parts in an automotive structure. This drive has prompted the need to design new systems for joining plastics to metals that are robust in an industrial environment. Current methods for stable joining of plastics and metals include adhesives, mechanical joints and overmoulding that involve a large number of assembly operations. The EU-funded project PMJOIN(opens in new window) (Development of a direct laser joining of hybrid plastic-metal components for industrial applications) overcame the drawbacks of state-of-the-art methods by developing a new innovative thermal joining concept for metals and plastics. PMJOIN developed a new laser-based process that eliminates the need for additional materials, adhesives or other bonding elements. In a two-step process, the metal surface is first structured with the laser. Then, the plastic is heated with the laser and bonded with the metal part. Precise control of the laser energy on the focal spot minimises thermal conduction to the surrounding material, ensuring high-accuracy bonding. Thanks to the use of flexible beam guiding systems, the laser joining system offers greater flexibility compared to mechanical joining and adhesive bonding. Being much faster and involving higher joint resistances, this new process also significantly reduces environmental impact. PMJOIN has spurred a new wave of research aimed at improving plastic-metal joints to ultimately help decrease vehicle weight. Furthermore, the project will lead to an increase in the speed of joining processes on the assembly line, translating to more economic and efficient production.