Novel polyurethane foaming process with reduced isocyanate content

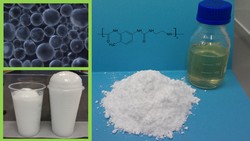

More than 50 000 EU companies employing 1.6 million people are active in the PUR foam sector. Isocyanate is one of the main components of PUR along with polyol, the two of which react in the presence of various additives to produce PUR foam. Isocyanate poses a threat to occupational health and has been associated with 10 to 20 % of asthma cases in the EU. The FREEFOAM(opens in new window) (Novel PUR foaming manufacturing process with reduced toxic isocyanate content) project has therefore developed a novel solution to this challenge based on the use of encapsulated isocyanate. The homogenous reaction resulting from the mixture, consisting of the encapsulated isocyanate dispersed in the polyol, enables the controlled release of the isocyanate. This increases the overall reactivity and prevents the reaction from taking place until it is appropriate to do so, thereby reducing the amount of free isocyanate required. In turn, lower residual isocyanate content in the foam minimises release into the environment. Additional benefits include a more homogenous foam product and a reduction in waste, which was previously generated due to poor homogeneity of the reaction mixture. Project partners investigated a number of different isocyanate formulations, leading to selection of toluene diisocyanate for encapsulation. Potential applications include the controlled release of inner material with specific properties under specific temperature and pH conditions. This new method can be used in the pharmaceutical, cosmetic, chemical, agriculture and food sectors. A total of 14 new ionic and non-ionic surfactants have been prepared, characterised and tested. Their influence in the capsule formation process and the stability of the obtained capsules over time was carefully studied. The team also evaluated the foaming process, assisted by the development of methodologies to quantify the isocyanate released after breakage of the capsules. FREEFOAM has created a new and advanced PUR foam system with enhanced properties and reduced toxicity to give a safe, environmentally friendly product, resulting in a reduction in imports and an increase in European exports. Furthermore, small and medium-sized enterprises associated with the project have new technical knowledge that will allow them to create better products and services and improve their understanding of the needs of end users, while manufacturing more homogenous PUR foams.