High-efficiency and high-power density electrical motors without reliance on rare earth materials

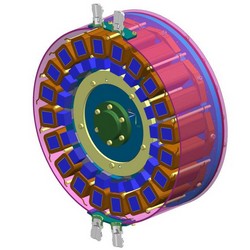

Global supply of these materials mainly rests on China, and they cannot be supplied in adequate volumes at a competitive cost. What is more, the future availability and price of rare earth magnets remains grim. Many experts foresee a supply deficit of some rare earth metals, as demand is expected to exceed the industry’s ability to produce these rare earth elements. The EU-funded VENUS(opens in new window) (Switched/synchronous reluctance magnet-free motors for electric vehicles) project set out to develop an electric drive system for EVs that does not contain scarce magnet materials, meets EV efficiency and power density performance, and is feasible for mass production. Work began by designing a prototype motor with an original electromagnetic configuration. The mechanical design differs from conventional radial-flux machines. To this end, project partners developed specific electromagnetic design and calculation tools, and advanced thermal models. They also developed power electronics. These include a new inverter consisting of a control board, interface board, driver board, semiconductor device, cooling system, DC-Link capacitor and aluminium housing. For the control system, a switched reluctant machine model was implemented with non-linear flux linkage. With the design in place, the VENUS team manufactured the components. The full motor assembly was then tested and integrated into an electric van. The power density achieved by researchers is 10 % better than benchmark motors without permanent magnets in low-powered vehicles and two-, three- and four-wheel vehicles. They also calculate that the inverter can provide the highest power per litre in the market: 19 kW/l (320 kW in 16.8 l). To exploit the motor, a comprehensive industrialisation analysis was carried out, including cost evaluation, manufacturing processes and required investments. VENUS developed a motor that can provide similar performance at a competitive price and reduced size. The absence of rare earth magnets in the motor means that no supply shortage will ever occur in key components during mass production.