Perfecting the biotechnological production of chitosans

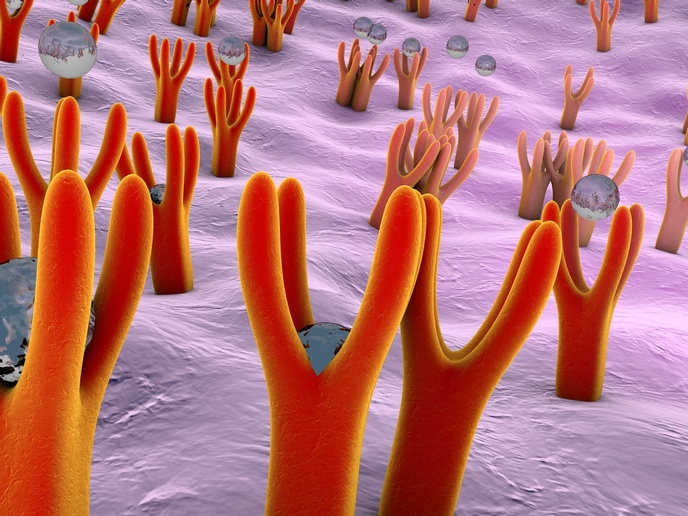

Oil production is slowing and, as a result, renewable resources are becoming increasingly important. In the near future, the biological production of raw materials will have to play an even greater role if we are to meet customer and industry needs in an environmentally friendly manner. To help facilitate this transition to the biological production of raw materials, the EU-funded NANO3BIO project has developed a process for the biotechnological production of chitosans. The huge potential of chitosans Chitosans can be used as raw materials by the medical, agriculture, water treatment, cosmetics, paper and textile industries, as well as many other applications. For example, one specific chitosan is suitable for finishing seeds to protect them from pests and diseases and to yield richer harvests. Another acts as an anti-bacterial, film-forming agent in the spray plaster that accelerates scar-free wound healing. In medical applications, specific chitosans can ensure the transport of drugs to their target sites (e.g. in the brain or in cancer cells). ‘Chitosans are typically obtained by chemical means from such limited resources as the shells of crabs and shrimps or, rarely, from fungi or squid pens,’ explains project researcher Achim Hennecke. ‘In the biotechnological processes targeted by the NANO3BIO project, specially optimised fungi, bacteria and algae will take over the production of chitosans.’ According to Hennecke, these so-called third generation chitosans benefit from more defined – or even novel – structural characteristics, clearly defined biological activities and known cellular modes of actions. As a result, they not only create new market opportunities, they are also more efficient, more environmentally friendly and less expensive than using currently available methods. A menu of important breakthroughs The NANO3BIO project has already achieved breakthroughs in several important fields. For example, researchers developed protocols for producing chitosans with better defined structures and a low-cost protein engineering technology to support their biotechnological optimisation. They also successfully isolated and identified the first natural chitosans produced by microalgae. ‘The project has identified genes from different organisms that can be used to drive the biotechnological production of chitin and chitosan modifying enzymes,’ explains Hennecke. ‘These were then characterised and used for the biotechnological conversion of chitin into new, high-quality chitosans.’ For example, NANO3BIO researchers successfully developed electro-spun chitosan nanofibers and electro-sprayed chitosan nanoparticles as technological platforms for the encapsulation and efficient release of bio-actives, vaccines and drugs. They also invented thermos-sensitive chitosan hydrogels, which are promising materials for regenerating damaged tissues. Another important outcome of project is its significant insight into the internalisation of chitosan nano-capsules into human cells, a breakthrough that promises targeted delivery of chemotherapeutics to cancer metastases at a very early stage. ‘This lays the groundwork for the development of more effective therapies with reduced adverse effects and better quality of life for patients,’ says Hennecke. According to Hennecke, many of these achievements have huge economic potential. ‘The NANO3BIO project has achieved encouraging results,’ he says. ‘As chitosans are non-toxic, the project has contributed to building an environmentally sustainable European economy and strengthening the competitiveness of European industry and SMEs.’