New technology for improved sensitivity of mammograms

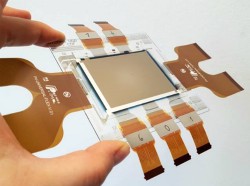

Specialised medical imaging uses a low-dose X-ray system to examine the breast for early diagnosis and screening. Despite solid evidence of benefit for women aged between 40 and 74 years, false positives result in additional testing and anxiety. False negative results, especially in the case of high breast density lead to a false sense of security and possible delays in appropriate treatment. The EU-funded project DiCoMo(opens in new window) used advancements in photonics to develop a digital flat-panel X-ray detector. Enabling low-cost and safer X-ray diagnosis, it exposes patients and radiology staff to lower-radiation doses. As project coordinator Dr Sandro Francesco Tedde explains, “This was achieved by combining radical innovations from leading European players from various disciplines, commercial and research partners from across the organic and medical imaging value chain.” Less radiation, better resolution In direct conversion, X-ray photons are converted directly into electrical signals. Conversely, for indirect conversion, X-ray photons are first converted to visible light and afterwards to an electrical signal using a photodetector. Although indirect conversion produces lower radiation doses compared to its counterpart, this comes at the expense of the image quality due to optical crosstalk between pixels. DiCoMo reconciled high-resolution imaging with exposure to lower-radiation doses by combining the best of both techniques. Radical advancements in the backplane and frontplane parts of the device convert X-rays via ‘active’ pixels and direct converting metal-organic perovskites photodetectors, respectively. Frontplane technology Since the initial DiCoMo approach of embedding scintillating microparticles in an organic semiconducting matrix did not deliver the targeted sensitivities, in particular for thick converting layers, a new and promising direct converting class of materials has been used: the metal-organic perovskites. Semiconducting perovskites combine the high absorption efficiency of indirect converters with the high resolution capabilities of direct converters. Project members have developed a novel solvent-free processing technology to ‘soft sinter’ perovskite powders on the demonstrator backplane. During pressing, perovskite microparticles were compacted, leading to the formation of a high-quality thick homogeneous layer stacked on top of the backplane substrate, displaying no optical cross-talk between pixels. Backplane technology Current mammography systems are typically based on passive pixels which relay on a single switching transistor made usually from a thin film of amorphous silicon. DiCoMo, however, used active pixel sensors made from three metal-oxide thin-film transistors, generating an in-pixel amplification, combined with a custom-made low-noise readout integrated circuit (ROIC). The design is optimised to convert signals coming from large-area pixels (e.g. >50µm pitch) and resulted in significantly enhanced sensitivity. “With its demonstrator in the size of a video graphics array (640x480 pixels), DiCoMo has delivered an essential building block for better and more affordable healthcare,” says Dr Tedde. Integration in a prototype “Complex engineering work resulted in successful design for the reading and driving electronics system for the DiCoMo X-ray imager,” says Dr Tedde. The low-noise ROIC is custom made by a consortium member. The chip-on-flex ROIC solution has demonstrated to be the best solution in terms of thermal budget compatibility of the different system components. “To the best of our knowledge, this is the first time that an active pixel backplane with low-cost indium gallium zinc oxide technology in a flat-panel X-ray detector is presented,” adds Dr Tedde. The team used the system to produce its first image, the Mona Lisa. Although there is still room for improvement, DiCoMo has significantly enhanced the competence and scientific know-how in this field and expects that project outcomes will strengthen the global competitiveness of the European medical-imaging industry.