Next-gen coatings for spacecrafts

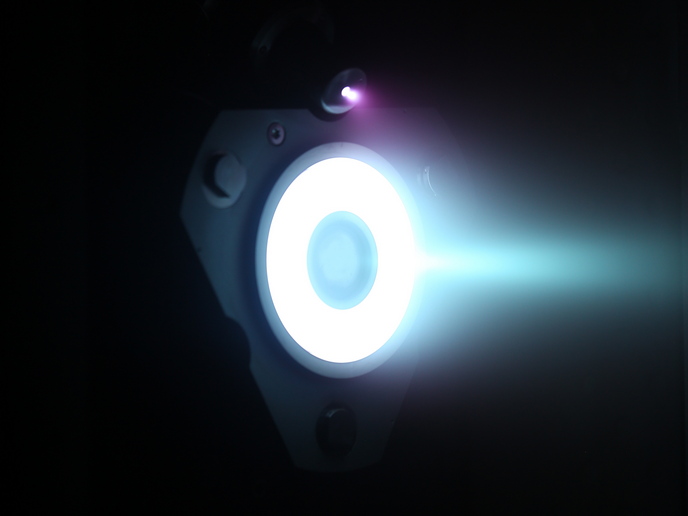

The OSR market is currently dominated by quartz OSRs and, to a much lesser extent, silver/Teflon foils. With its metamaterial OSRs (meta-OSRs), the META-REFLECTOR consortium offers the best of both worlds: the space durability of quartz OSRs with the flexibility and ease of use of Ag/FEP foils. “Quartz OSRs tend to break during application. They are not compatible with curved or bendable radiator panels, and the only commercial alternative (Ag/FEP foils), whilst easier to handle and apply, does not age well in the space environment. Moreover, both technologies maintain high emissivity even at low temperature, which is a cause of heat losses during eclipses,” says Lucia Amorosi, Project Manager at Thales Alenia Space and coordinator of META-REFLECTOR. Meta-OSR coatings, on the other hand, have the potential to eliminate these problems. Thanks to the use of thermochromic metal oxide, they even feature temperature-variable emissivity, in turn enabling considerable power savings. The technology is also entirely based on durable and space-approved inorganic coatings, and it can be applied to flexible thin-film substances. Unlike quartz-OSRs, which are produced by depositing a continuous metal layer on the second (radiator-facing) surface of quartz tiles; meta-OSRs are produced by depositing a metal/dielectric metamaterial coating on the external (space-facing) surface of polymer foils. “We use the term ‘metamaterial’ to imply that one of the layers of the coating is patterned into a 2D array of nano-antennas. This patterning is accomplished by Nano Imprint Lithography, a technique that is easily scalable to large areas at fair costs,” Amorosi explains. Along with this coating, the team could also demonstrate a smart radiator using a similar metamaterial design. The latter allows for tuning the radiative cooling of the spacecraft using another type of metal oxide. The path to commercialisation Although the technology fully met the consortium’s initial expectations, Amorosi admits that there is still some work to do before it can be commercialized. “Further R&D work is needed to fabricate breadboards that fully meet the thermo-optical requirements of the application,” she points out. When this process will be completed, flexible and space-durable OSRs with temperature-variable emissivity will finally be available to satellite and spacecraft manufacturers. As the meta-OSRs can be implemented on extremely thin foils, the team envisages a large panel of space applications, from specialty MLI to solar sails, thermal covers for antennas and inflatable structures of different kinds and for different uses. “In principle, meta-OSRs could be used also in terrestrial applications such as super-cool roofs for energy efficient buildings. The main challenge here, however, is the relatively high cost of the technology,” says Amorosi. With META-REFLECTOR now completed, the consortium is actively looking for new funding opportunities to complete the development of their technology and build demonstrators that fully meet application requirements. Amorosi expects the technology to start being embedded on spacecrafts within the next 5 years.