Furthering liquid crystal technology for more flexible, intelligent and functional materials

Greater knowledge of LCs will enable novel approaches in applying them to contexts entirely different from tablets and mobile phone displays – their current most common use. LCs have enormous potential for many emerging technologies because they survive great degrees of repeated stretching and flexing thanks to their liquid, lightweight nature, and often their operation requires no electricity. What’s more, LCs have a rather low manufacturing cost.

Work on shape-changing LC elastomers (LCEs) leading to interesting, unexpected findings

The European Research council (ERC)-funded INTERACT(opens in new window) project has gained deep insight into how LCs behave when departing from the standard flat geometries in which they have been studied and used for decades. INTERACT has discovered totally unforeseen features, such as an LC with an anti-ordered arrangement of its constituents, where molecules are arranged to avoid a certain direction rather than align along it. “This so-called negative order parameter LC had been conceived theoretically before, but was never observed in practice; we produced such a material in the context of our shell-shaped LC elastomer actuators,” outlines ERC grantee and principal investigator Jan Lagerwall. LCEs are a unique class of materials that exhibit large shape transformations when subjected to various stimuli. These materials can be used as actuators – devices that convert some type of stored energy into motion. “Because of the reverse ordering, the material responds to temperature changes in the exact opposite direction of conventional LCEs,” he explains. The INTERACT team has also produced valuable new understanding of how to flow LCs and polymer solutions next to each other. This is required for making LC-functionalised fibres that could be used for responsive textiles, for example. “This is truly challenging for many material combinations, but our research gave us a much clearer picture of how undesired outcomes can be avoided,” says Lagerwall. “We also made significant advances in the methods for retaining liquid crystalline order in rubbery or solid states by polymerising the system without negative impact on the order.” Thanks to these scientific achievements, Lagerwall continues, the project “has gotten closer to new LC applications, at least in wearable technology and secure authentication.” INTERACT now has “a relatively clear understanding of how LCs can indeed be incorporated into real textile-grade fibres that could be used for garments.”

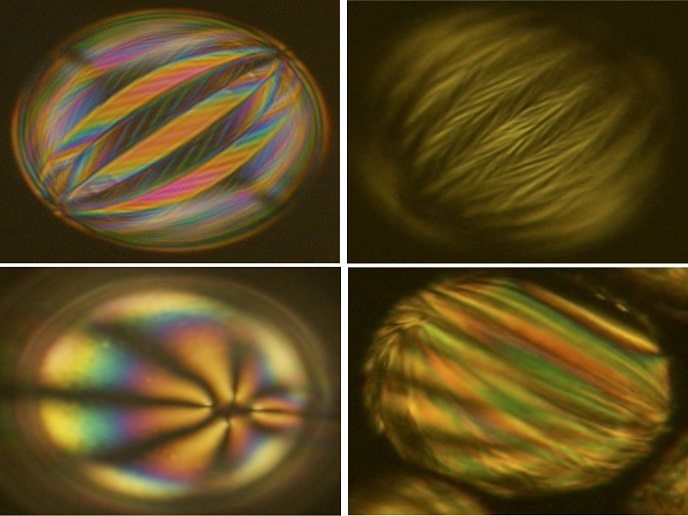

Secure authentication tag breakthrough

The researchers have made authentication tags that provide a unique fingerprint for a target object. The tag is made in such a way that it is really integrated into the object, serving as a highly reliable anti-counterfeiting tool. The team has succeeded in turning the tags from colourful to nearly invisible, thus allowing them to be adapted to the environment in which they will be applied. “We believe they can become entirely invisible by further optimising the materials used,” the principal investigator adds. Scheduled to end in March 2020, the team has already submitted one patent application for their materials, and two more are being prepared. Ongoing experiments target true textile-grade fibres with LC inside, as well as the realisation of tubular LCEs. For materials scientists and LC physicists, chemists and engineers, INTERACT has clarified several important questions on how to bring LCs into complex geometries like fibres, shells and tubes. The project has demonstrated that the behaviour of the LC can be very rich, depending on how the sample was made and what its characteristics are. For engineers and industry overall, “I sincerely hope that the results of INTERACT can inspire new LC applications, solving old problems and emerging ones in new, better and more sustainable ways by using LCs derived from cellulose,” concludes Lagerwall.