Ready to motor: It’s metal nanoparticles’ turn to shine as catalysts

Materials that increase the rate of a chemical reaction, while remaining unchanged in the process, known as catalysts, lie at the heart of many technologies. A familiar example comes from automobile exhaust systems that change toxic fumes into more benign gases. Unfortunately, catalysts are often expensive because they typically contain one or more precious metals, such as platinum, rhodium or palladium, whose supplies are limited. The EU-funded PROMETHEUS(opens in new window) project has found a route around this limitation in the automotive sector: a way to retain the same catalytic efficiency with as little as approximately one-tenth the amount of precious metals. “Until now, the quality of the automotive catalytic converters was thought to be analogous to the quantity of the platinum-group metals (PGMs) the catalyst contains. PROMETHEUS proves nanotechnology aids in producing automotive catalysts with 85 % fewer precious metals, while maintaining the same performance with the commercial catalysts used in vehicles that comply with the Euro 6d emissions standards,” notes Iakovos Yakoumis, PROMETHEUS coordinator and founder of the coordinating company MONOLITHOS Catalysts(opens in new window).

Nanotechnology is the key to increasing reactivity

To meet the increasingly stringent emission standards, car manufacturers are forced to load more PGMs into the catalytic converters. The PGMs have a high selective catalytic reduction efficiency, meaning they can reduce nitrogen oxides into harmless nitrogen and water. PROMETHEUS synthesised instead nanomaterial-based catalysts in the form of powder that prevent the agglomeration of metal particles. Unlike their bulk counterparts, nanoparticles have a larger surface area that enhances properties such as catalyst reactivity. “The novel catalyst is based on copper nanoparticles. Copper has a relatively low catalytic efficiency compared to other PGMs. To compensate for this, MONOLITHOS added a higher amount of copper in the catalyst mixture which induces a negligible cost,” explains Yakoumis. Despite its surging price, copper is still far less expensive compared to other PGMs.

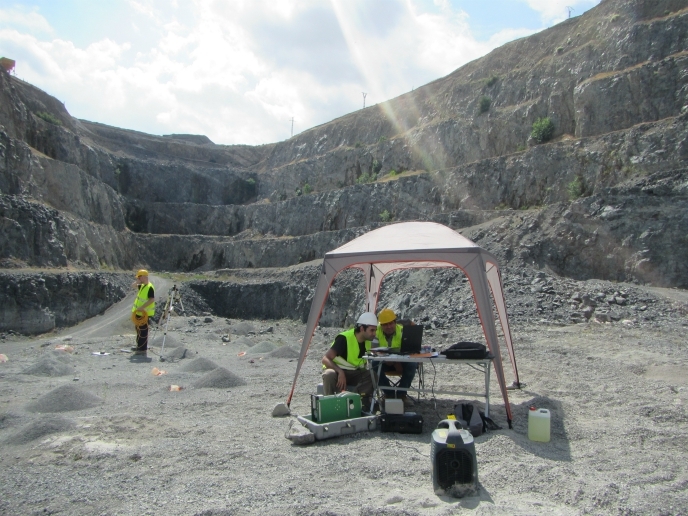

A detailed picture of the catalyst preparation process

For the first time, researchers succeeded in synthesising large batches of active catalyst powders (exceeding 100 kg) containing copper, palladium and rhodium. For the synthesis of the heterogeneous nanocatalysts, they employed a commonly used method known as wet impregnation. The sol-gel process aided in depositing the nanoparticles on the monolithic catalyst support. The catalyst carrier has been optimised to achieve the highest possible active surface and oxygen storage capacity – both play a key role in the catalytic activity of oxidation reactions. Researchers also used a special binder to achieve homogeneous impregnation of the catalyst in the walls of the monolithic substrate. All materials were characterised using different microscopy techniques. To efficiently measure the catalytic activity for the multi-gas emissions (carbon monoxide, nitrogen oxides and methane) humidified with water vapour, MONOLITHOS used a synthetic gas bench. This unit creates gas atmospheres and reaction temperatures characteristically found in automotive catalytic converters. To test catalyst ageing, the company placed the catalysts in an oven that carries hydrothermal reactions at high pressures and temperatures. Prometheus catalyst proved its endurance after hydrothermal ageing (containing 10 % water) at 1 050 °C for 4 hours and at 850 °C for 16 hours. “Despite limiting PGM usage to 15 %, our catalysts demonstrated similar activities to commercial Euro 6d catalysts,” notes Yakoumis. Until now, several lines of attack have been pursued to shrink the PGM content in catalytic converters. Fashioning the metals into nanoparticles just like MONOLITHOS did provides a real push to greener vehicles running on the road.