Automated ultrasonic scanner monitors railway frogs

The places where two railway lines cross or diverge feature complicated X-shaped track-switching mechanisms. Called points, these include a fixed V-shaped structure called a frog. Frogs are the only places where train wheels lose contact with the track. Each wheel jumps a small gap, causing continual repetitive impact on the frog. Since frogs are subject to high wear, which can potentially cause breakage and thus train derailments, they are made from extremely hard manganese steel. Yet, this only reduces, but does not eliminate, the need for inspection. Current inspection methods each suffer difficulties that affect their viability. For example, optical methods can only detect superficial defects. Radiographic (X-ray) methods are expensive and hazardous to inspectors. Current ultrasonic methods suffer too much acoustic backscatter when applied to manganese steel.

Frog inspection

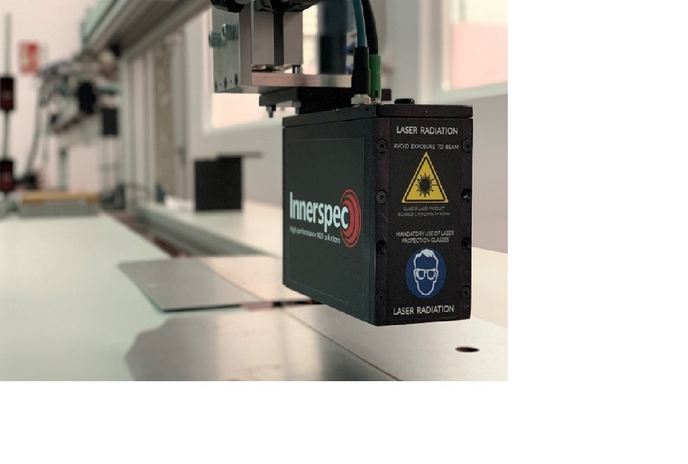

Inspection of frogs has conventionally required their complete disassembly. This is extremely time-consuming and expensive. To avoid these costs, railway engineers replace frogs more frequently than necessary, which is prudent although still expensive. So, the EU-funded SAFTInspect(opens in new window) project developed a new, automated, ultrasonic frog inspection device able to detect subsurface defects. In addition to the scanner, the team also developed data-processing algorithms and associated software. The device consists of a wheeled frame, called Cross Inspect, that travels along the track. The frame detects the presence of a frog as it passes over it. Electromagnets fasten the frame to the frog to allow scanning and then disengage when scanning is complete. While attached, two separate motors sweep an innovative ultrasonic scanner along and across the surface of the frog. The scanner features several recent advances that allow scanning of manganese steel. Ultrasound echoes bounce off any defects in the steel.

Analysis and visualisation

A transducer relays the collected echoes for remote processing and analysis. “The transducer also includes multiple mechanisms that squirt water on the frog, as an ultrasound medium,” explains Roberto Puyol, project manager. A separate analysis unit, including project-developed algorithms, processes the echo data. This yields 2D and 3D images of any defects. The system monitors the evolution of the defects. Depending on the condition of the frogs, the system recommends appropriate maintenance actions. These might include replacement of the frog or a temporary restriction of train speed along certain sections of track. “The results have been very satisfactory,” reports Puyol. “We have been able to detect 0.5 mm cracks in the frogs down to a depth of 5 cm.” Testing also demonstrated the effectiveness of the project’s visualisation technologies. Despite the promising results, it is still early days. A Spanish government railway authority has expressed interest in using the SAFTInspect system to check the integrity of frogs on a 15-m section of crossing. Before this will be possible, the team needs to tweak the hardware and redesign the software. The team will also be working on additional methods that address the limitations of optical and X-ray scanning techniques. When ready for widespread release, SAFTInspect will provide a reliable, convenient and inexpensive way of monitoring the state of railway frogs.