AI-powered robots transform road repairs in Europe

Road maintenance is essential for safety and economic growth, but it remains one of the most hazardous and costly public services. The EU-funded HERON(opens in new window) project set out to automate these operations, creating the first integrated robotic platform that can patch potholes, seal cracks, repaint markings and even handle pre- and post-work tasks like cone placement and reporting.

Tackling the complexity of ‘messy’ road materials

Automating roadworks is not as simple as replacing workers with robotic arms. Materials such as bitumen(opens in new window) and aggregates behave unpredictably, shifting with changes in temperature and humidity. As project coordinator Nikos Bakalos recalls: “The most counterintuitive challenge was not the precision of the robotic arm, but the ‘messy’ nature of the materials themselves. Bitumen and aggregates don’t behave like obedient industrial parts; they’re moody, shifting their viscosity and stickiness with every change in temperature and humidity.” These difficulties required advanced sensing and control strategies, ensuring the system could cope with variations that human crews handle instinctively.

Navigation and decision-making in real environments

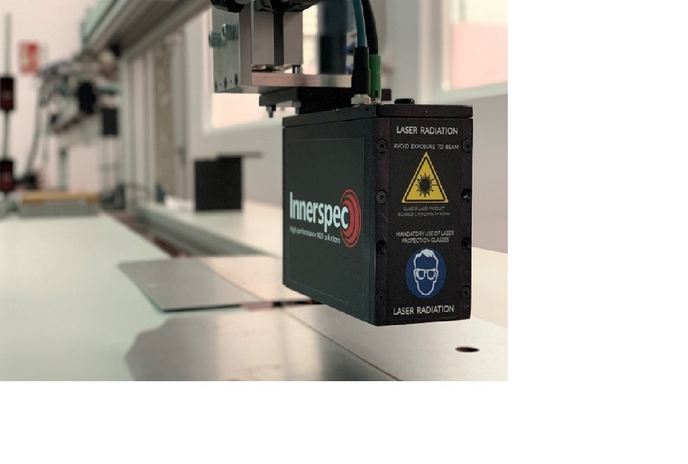

HERON vehicles were designed for highways and urban roads, where traditional navigation tools face significant trade-offs. Real-time kinematic global navigation satellite systems(opens in new window) (RTK-GNSS) can provide centimetre-level accuracy but lose reliability in tunnels or underpasses. Simultaneous localisation and mapping(opens in new window) (SLAM) methods, which build maps from sensors such as cameras or light detection and ranging(opens in new window) (LiDAR), a laser-based system that creates 3D maps of the surroundings, offer local consistency but often drift in repetitive highway settings. The team’s solution was to fuse both approaches, ensuring robustness across environments. Once defects were detected, the challenge shifted to planning interventions. HERON developed hybrid man–robot workflows where operators could supervise and adjust robot actions in real time. Bakalos explains: “In practice, a fully autonomous pipeline remains difficult under these conditions, and a hybrid man–robot approach is currently more suitable.” This design ensured the system could balance automation with human oversight, especially in complex maintenance scenarios.

Embedding AR and VR into daily operations

While augmented and virtual reality tools are often treated as optional extras, HERON embedded them into the platform from the start. These tools improved situational awareness, allowing remote staff to visualise defects, simulate workflows and validate interventions without direct exposure to traffic. As Bakalos notes: “AR and VR became mission-critical once we recognised the importance of situational awareness, both for the control centre and for staff working directly on the road.” This reduced operator risk while making inspections and interventions faster and more reliable.

Adoption in real road agencies

By combining drones, ground robots, AI-based detection and immersive visualisation, HERON created a multi-purpose maintenance ecosystem. Beyond technical performance, the project highlighted the need for updated procedures and procurement frameworks so that agencies can adopt robotics as a regular part of operations. With its demonstration of automated defect detection, safe robotic intervention and integrated reporting, HERON marks a step toward predictive maintenance and use of digital twins in infrastructure management.