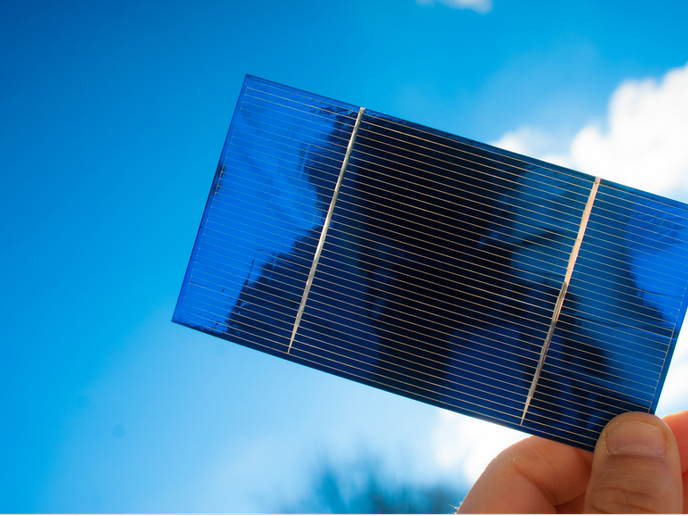

Towards a brighter future through third-generation solar cells

The third generation of solar cells is at our doors. Whether it’s organic photovoltaics (OPVs), quantum dot or perovskite solar cells, all third-generation technologies promise smaller cells with higher power efficiency – at a lower price tag. But there is a serious obstacle on the path to commercialisation: Third-generation cells are so tiny and complex that by the time they are fully manufactured, we’re not so sure how they are structured any more. “The optimisation of third-generation solar cells, organic or inorganic, is very much a process of trial and error,” says Jens Andreasen, specialist in researching synchrotron-based 3D imaging of energy materials at DTU Energy and principal investigator of the ERC-funded project SEEWHI (Solar Energy Enabled for the World by High-resolution Imaging). “This has a double effect. First, it seriously delays the search for optimal material combinations, since testing has to be done on completed devices for every process parameter. But more importantly, better performing systems may be completely overlooked.” Andreasen has a plan to tackle this issue. In May 2016, he began developing novel 3D imaging techniques based on X-ray ptychographic tomography and 3D X-ray diffraction. If successful, his efforts would enable discrimination between materials showing very subtle differences at high spatial resolution.

Nanostructures revealed

Take organic solar cells for instance. They consist of light elements with small variations in density. Studying the nanostructure of these elements calls for a technique providing some contrast between different microstructural irregularities at the nanoscale. Although this is key to correlating photovoltaic performance with processing conditions, it was almost impossible to achieve before SEEWHI. “We are close to identifying differences at a resolution higher than 10 nm in 3D. Before this project, the nanostructure of organic solar cells was not known from direct observation but rather inferred from modelling. We just didn’t know for a fact what structure the best-performing solar cells had,” Andreasen explains. Once the actual nanostructure is established thanks to X-ray imaging, Andreasen can correlate these structures with models of photovoltaic performance and molecular dynamics. This allows him to determine the relation between processing parameters and the resulting structure. “We can then establish a feedback loop that allows us to manufacture solar cells with an optimally performing nanostructure,” he notes. SEEWHI is a year away from completion, yet early results have been quite encouraging. The team notably devised new algorithms for the 3D reconstruction of ptychographic tomography data. These are hoped to allow the imaging of complete solar cells in 3D at 10 nm resolution, at least as soon as they can be combined with a fourth-generation synchrotron. “There is more,” Andreasen adds. “We have achieved unprecedented characterisation of a kesterite (CZTS) solar cell. We are also very close to having a scheme that allows us to model the optimal structure of any organic solar cell materials system. We will also soon be able to determine the processing parameters required to realise such structure in a large-scale solar cell.” By the time the project comes to an end, the team hopes to demonstrate a photovoltaic modelling of the 3D nanostructures they measured and modelled. Should fourth-generation synchrotron sources become capable of carrying out the appropriate 3D imaging experiments soon, they could also show the 3D nanostructure of an organic solar cell with sufficient resolution to distinguish its donor and acceptor domains. “My hope is that we will succeed in providing a roadmap allowing experimenters to bypass years of trial and error and find out about overlooked opportunities. Eventually, this may lead to a major breakthrough, not only for organic solar cells, but for many technologies relying on self-organisation of structure from the atomic to the mesoscale,” Andreasen concludes.