New alternative to endoscopy and biopsy for patient comfort on the horizon

EU-funded BiOp-FibEnd project researchers adapted the conventional fabrication technology for optical fibres(opens in new window), so called ‘fibre drawing’(opens in new window). Basically, a preform is fed into a furnace, which after heating, becomes soft allowing it to be pulled into a fibre. “To achieve the sub micron diameter tolerance necessary for this research, we had to establish a robust and stable drawing system dependent on the environment where the fibre is produced,” outlines Alessio Stefani, BiOp-FibEnd fellow.

Novel materials, new applications

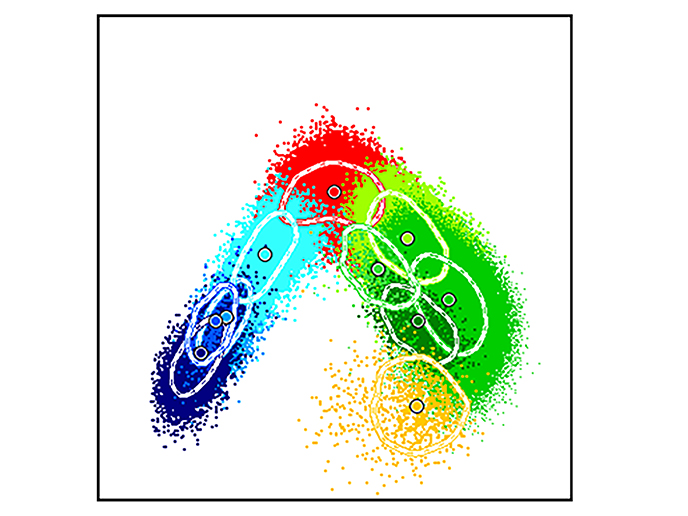

The BiOp-FibEnd team used new materials for the first time bearing in mind their application in the exploration of body tissues. An application they had not considered at first was blood pressure measurement. “We chose polyurethane(opens in new window) which has high elasticity, like a rubber band, to develop a sensor which indirectly measures blood pressure giving a highly accurate reading during both walking and running,” explains Stefani. The ingenious method uses two parallel fibres, each with a light source and a detector. The pulse deforms the fibre and then perturbs the light signal proportionately. The timing difference of the pulse at each fibre calculates the pulse wave velocity or blood pressure(opens in new window). The research team pushed the limits of the structures produced with fibre drawing, resulting in dielectric structures with 500 metal wires of an average diameter below 150nm. Multimaterial hyperlenses(opens in new window) fabricated by these structures provided super-resolved imaging in the mid-infrared range(opens in new window) at wavelengths of 3-4 micrometres and focusing on a spot 176 times smaller than the wavelength in the THz regime(opens in new window). Another important project outcome was a catheter that enables recognition of the differences between the various tissues in the heart by combining spectroscopy and artificial intelligence. A patent has been filed for this technology.

Unexpected drawbacks lead to solutions also

“The most unlikely challenge for the team was that the smallest amount of light destroyed the hyperlenses while operating in the mid IR range. The samples, the tiny metal wires, melted,” explains Stefani. Researchers investigated the solutions to this problem, at least theoretically due to the obvious time constraints. “The simulations to check the soundness of these alternative proposals are quite promising. However, together, these solutions are worthy of a project all of their own, and therefore, it wasn’t reasonable to investigate them all experimentally,” says Stefani. The answer was to invest the remaining time in the most promising part of the project, the blood pressure monitor, the main medical application.

Realistic research steps forward with funding opportunities

The team are pragmatic and optimistic about what lies ahead in terms of future research. Understanding the limitations of the system, they therefore have potential solutions. “We are actively engaging in conversation with private and public funding partners to move the blood pressure-monitoring system towards a commercial product, and a patent has been filed,” he says. Highlighting the importance of team working, Stefani points out that BiOp-FibEnd was funded by a Marie Skłodowska-Curie Individual Fellowship. “However, having one person doing the work on their own would not be enough to achieve the range of results we obtained. Everyone working towards a similar goal made it more efficient, yet advanced in various directions and investigating different scenarios,” he concludes.