Robots that are built to build

Currently, the presence of autonomous systems in the building and construction sector is nearly non-existent. While other industries have quickly digitised, most construction tasks remain largely manual, performed using equipment that requires a high level of human supervision. This, in part, is why the sector has a high accident rate. According to data collected by Eurostat in 2018(opens in new window), one in eight workplace injuries and one fifth of all fatal accidents occur in the construction industry. Another common problem related to the industry’s heavy reliance on manual processes is a lack of structural quality in some projects and the extra time needed to remedy these inaccuracies. With these problems in mind, the project HEPHAESTUS (Highly automatEd PHysical Achievements and PerformancES using cable roboTs Unique Systems) is on a mission to introduce advanced robotics to the construction sector. “We believe that robots can automate some of the tasks that are now performed manually, such as the installation of facades,” says Julen Astudillo, a researcher at Tecnalia(opens in new window), the project’s coordinating partner.

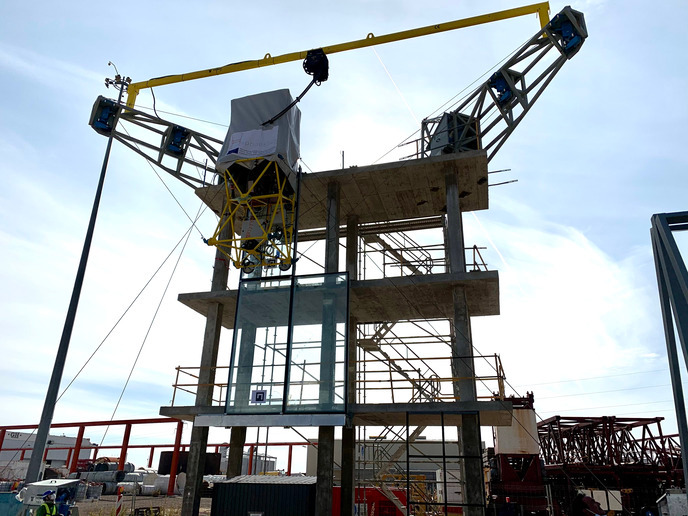

An autonomous, cable-driven robot

At the heart of the project is Hephaestus, an autonomous robotic system that can accomplish multiple tasks on the vertical and inclined planes typical of a construction site. “We believe that our system will not only improve safety, it will also increase the quality of the construction and reduce time and costs.” Hephaestus is a cable-driven robot that can be draped over the sides of a building. With the cables running from roof to ground, the robot can automatically move to different spots of the building’s facade with a high level of accuracy. It also has the capacity to hoist up to 1 000 kg, meaning it can transport heavy equipment to various points of the building site. Furthermore, because the robot’s end effector is modular, the same system can be used for multiple tasks. “On one side of a building, the robot could be performing all the tasks related to installing the prefab wall – drilling the concrete slab, inserting bolts, installing the facade modules – while on the other side it might be cleaning, painting, or repairing an already installed facade,” explains Astudillo. “All this with minimal human intervention.” Compared to other systems, Hephaestus has the noted advantage of being lean and easy to move. It is also compatible with other handling and support systems, such as gondolas, scaffolding, etc. The system is highly versatile and can be easily adapted for use on a wide range of building types.

The benefits of construction robots

The project demonstrated the benefits of using robotic systems in construction and, specifically, for installing facades. “With our system, companies can achieve a 20 % reduction in installation time and a substantial increase in installation quality,” concludes Astudillo. “But most importantly, the system significantly increases the safety of construction workers working at height.” Although the project is now finished, its nine partners(opens in new window) would like to further increase the flexibility of the system and add new tools to its end effector. For this, they are currently looking at additional funding opportunities and to partner with other companies working in the facade and construction fields.