Advanced drilling technology optimises aircraft manufacturing and assembly operations

Orbital drilling, a process that mills holes using a specific tool, meets this expectation by producing quality drilling in a single operation through complex assemblies of metallic and non-metallic materials. “However, existing solutions aren’t compact enough or sufficiently precise to robotise the drilling of a series of small-diameter holes,” explains Jacques Prono, coordinator of the EU-funded RODEO(opens in new window) project. “Furthermore, the metallurgical condition of aluminium around the holes has to be controlled to guarantee the fatigue strength of the assembly.” The RODEO team proposed an operational process for light robotic orbital drilling, as well as suitable cutting tools and operating conditions. These technological solutions provide precise drilling of tightly spaced, small diameter holes in aluminium with control of the induced residual stresses(opens in new window).

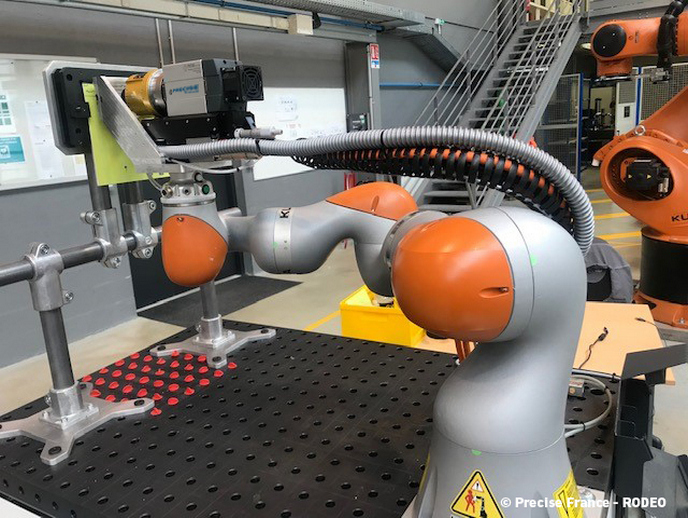

Integrated, lightweight and compact robotic orbital drilling system

Project partners conducted an in-depth study of the behaviour of aluminium alloys(opens in new window). The analysis highlighted the quality of the holes obtained through orbital drilling and the improvement of aluminium alloys’ fatigue strength under these drilling conditions. “This result is both unexpected and very positive, and studies are continuing on this subject,” notes Prono. They also developed and tested an innovative combined drilling and burnishing tool that controls the level of residual stresses in the hole wall, modifying its actions during fatigue. Test outcomes showed a significant increase in the level of residual stresses in the hole wall compared to a conventional orbital drilling method, especially on smaller-diameter holes. A patent application has been filed for the tool. Team members also designed and fully tested a compact and lightweight orbital drilling head to be integrated into an industrial robot. Thanks to its performance and very low weight, the head can be used on the end of a robot’s arm. To define and optimise the rigidity and resistance to vibrations, the RODEO team examined the adaptation of this drilling head on various robotic arms, and one of the arms proved suitable for such an application. The orbital drilling head has already been commercialised. Versions of the head to be mounted on machining equipment are also being developed and will soon be commercialised.

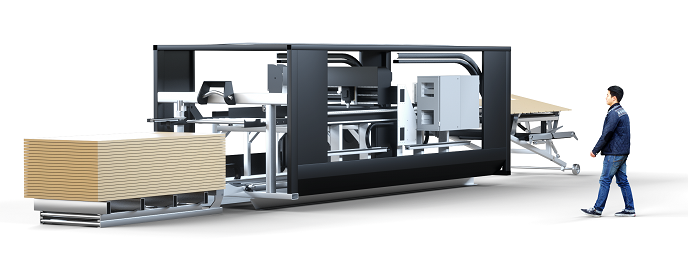

Towards efficient and agile orbital drilling technology for aeronautics

European companies that produce aeronautical assemblies and sub-assemblies can now robotise the drilling of many small holes required to assemble aircraft structures, in particular rivet holes. The cleanliness of the hole means that there is no deformation or burrs – raised edges or small pieces of material that remain attached to a metal piece after machining operations. “This process makes it possible to develop the drilling and robotic assembly of the structures in a single operation without disassembly for cleaning or control in between,” concludes Prono. “The potential productivity gains are therefore considerable.”