Next-generation aircraft could run on electricity even on the ground

A typical single-aisle aircraft making 8 to 10 flights per day spends a whopping 2.3 hours a day taxiing, using up to 13 kg of fuel per minute because aircraft engines are not optimised for ground movements. Electric taxiing could significantly reduce this consumption and offset fuel costs, offering clear benefits for airlines, airports and the environment.

How green taxiing works

Electric taxiing systems rely on electric motors embedded in the landing gear, allowing planes to taxi without using their jet engines – saving fuel; and also braking electrically thus reducing carbon emissions during ground operations. The technology enables aircraft to taxi autonomously under their own electric power; and also to reverse autonomously. The innovation targets short- and medium-haul aircraft, including the Airbus A320 and Boeing 737. “The EU-funded SUNSET project is contributing to the development of tomorrow’s most innovative technological solutions for electric aircraft. The general objectives are to reduce energy consumption, emissions and operating costs, positioning the EU as a global leader in low-emission aircraft development,” notes Xavier Benoit, innovation vice president at Centum Adeneo(opens in new window). The France-based electronics company is working on ways of recovering the energy wasted when an aircraft is queuing on a runway.

Enabling technologies

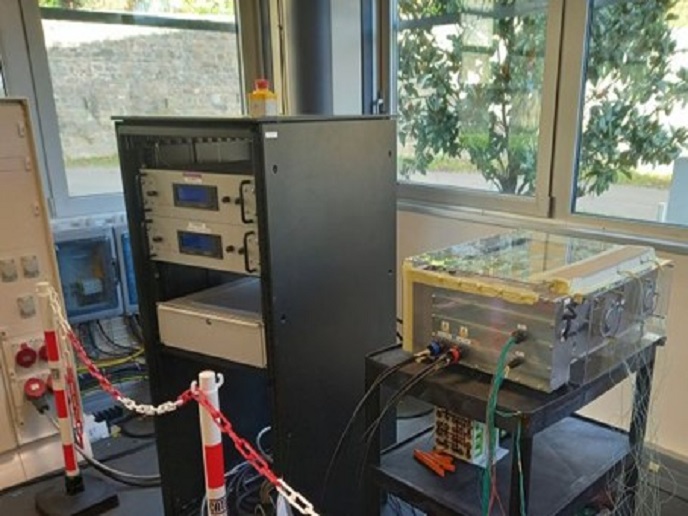

SUNSET includes a bidirectional power converter, together with a high-energy density module, which acts as an energy buffer, storing the amount of energy from the APU required to move the aircraft and returning it to the wheel engine, thereby optimising fuel consumption on the ground. “The aircraft engine will be fired during take off, flight and landing but will cease operation on the ground,” explains Benoit. Project researchers have come a long way in terms of developing all components included in the global system, such as the power converter, solid-state circuit breakers, battery management system, power controllers and all related software. But their groundbreaking concept was not without its issues, most notably the lack of a lightweight adapted energy storage module. Those that researchers intended to use are not available to the aerospace market owing to their excessive demand from the electric car market. “State-of-the-art batteries needed to work bidirectionnaly at sufficient power generates excessive weight, thereby largely determining the size of the energy storage unit built around them. The amount of energy stored in the demonstrator is thus 3.5 times higher than that originally planned for the energy storage unit,” notes Benoit. Now that the project ended, researchers have a clear view of the challenges that need to be overcome when it comes to embedding high energy density modules in next-generation aircraft. “We aim to contribute to the rise of more-electric aircraft, focusing not only on improving performance in flight but also during taxiing which is especially relevant for short-range flight,” Benoit emphasises. Advances in power converters and energy storage devices in single-aisle aircraft could reduce nitrogen oxide emissions by 51 %, carbon dioxide emissions by 61 %, carbon monoxide emissions by 73 % and unburned hydrocarbon emissions by 62 %. “They could also reduce the noise around airports during the taxi phase,” Benoit concludes.