Graphene composites take a step forward towards 3D printing of multifunctional cellular structures for electronics

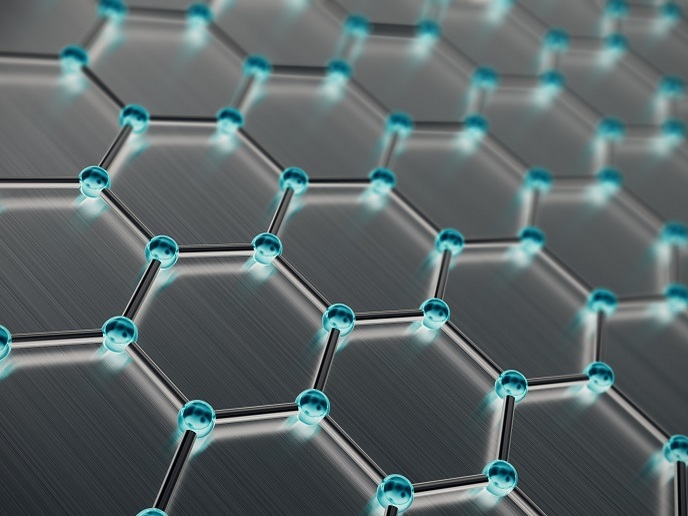

The extraordinary physical properties of graphene – a 2D layer of carbon atoms arranged in a hexagonal lattice structure – have spurred armies of researchers to explore its potential. Graphene is currently used in dozens of consumer and technological products, and there are high hopes for its use across several industrial subsectors. One development that could hasten industrial innovations built around graphene is graphene-based composite materials for additive manufacturing. With the support of the Marie Skłodowska-Curie Actions programme, the Graphene 3D(opens in new window) project provided a pathway to the development of optimised, multifunctional graphene-based polymer composites for 3D printing applications. Furthermore, using the new nanocomposites, the project targeted the development of structures with desired electromagnetic shielding and thermal properties.

Polymer composite materials with enhanced properties

“We prepared different composite formulations based on five types of polymers loaded with hybrid carbonaceous nanomaterials (a mix of graphene and carbon nanotubes),” notes project dissemination manager Patrizia Lamberti. All the formulations proved suitable for 3D printing and demonstrated good electrical conductivity, high electromagnetic shielding efficiency and improved thermal properties compared to the pure polymer matrix. They also preserved, and in certain cases even improved, the rheological and mechanical characteristics of the starting material. Researchers focused on fused deposition modelling(opens in new window) and selective laser sintering(opens in new window). Different materials were prepared for these 3D printing technologies using a mix of graphene nanoplatelets, reduced graphene oxide and multi-wall carbon nanotubes incorporated in polylactic acid, thermoplastic polyurethane, vinyl alcohol, polydimethylsiloxane, etc. “Certain composite materials generated in the course of the project are unique, whereas others outperformed those available on the market. The use of a robust design methodology greatly aided in producing composites with better global performances than current ones,” adds Lamberti. In addition, thanks to special preparation techniques, the electrical or rheological percolation thresholds were reduced significantly. “This is an important activity since it involves using a lower number of nanostructures to build composites with the same characteristics, “explains Lamberti.

Strong, lightweight carbon-based cellular materials

Different cellular material structures were modelled and fabricated with extraordinary electrical and thermal conductivity, mechanical strength, light weight, and efficient shielding against microwave perturbations. “The targeted application was to prevent electromagnetic interference in sensitive electronic devices by providing protective electromagnetic screens that absorb the incoming radiation rather than reflecting it back. Simultaneously, the shielding screen should not block the evacuation of the heat generated by power electronics,” explains Lamberti. Using fused deposition modelling and a mix of polylactic acid, graphene nanoplatelets and multi-wall carbon nanotubes, researchers fabricated three generic structures: anechoic pyramidal structures, periodic open-cell structures and ‘waffled’ structures. Furthermore, a ‘Russian nested doll’ prototype was fabricated from thermoplastic polyurethane and multi-wall carbon nanotubes using selective laser sintering. Linking three emerging different fields of activity, namely graphene-polymer nanotechnology, materials design and additive manufacturing, Graphene 3D enhanced interdisciplinary, strategic collaboration between partners, their reputation and provided the launching pad for future collaborative ventures. The project also created a ‘Joint Laboratory on graphene-polymer research and applications’ for knowledge sharing within the consortium. Four conference meetings and a training school were organised to disseminate project activities. Project results are published in 80 articles scientific journals with high impact factor.