Fungi could be the foundation of intelligent and sustainable buildings

Imagine a smart building made with green construction materials that can adapt to changes in light, temperature and air pollutants. This is the vision of a cross-disciplinary consortium of architects, computer scientists, biophysicists, mycologists and industry experts in mycelium-based technologies who collaborated on the EU-funded project known as Fungal Architectures(opens in new window), or FUNGAR. Their goal was to develop a fully integrated structural and computational living substrate using fungal mycelium. While this dense, durable and biodegradable filamentous scaffold has already been used to produce materials such as acoustic and insulation panels, the project marked the first time it has been used in a live, functional form.

A sustainable building material

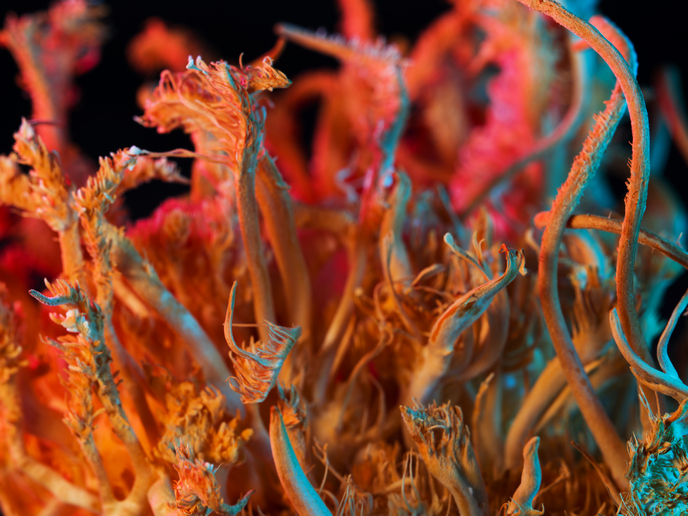

“Filamentous fungi can grow on waste streams from agriculture, horticulture and forestry. During growth, the hyphae (filamentous cells) bind the fibres of the waste stream together, resulting in a foam-like material,” describes Han Wösten, professor of Microbiology at Utrecht University(opens in new window). As a carbon sink material, mycelium composite could be one solution to address the need for reducing the environmental impact in the construction industry. To develop the mycelium composite, researchers combined fungal strains with different types of substrates and bioprocessing techniques. “Our project not only looked at the diet of the fungi, but also at their resistance to conductive materials that can be used to allow fungal hyphae to transport information. Combining both aspects, the conclusion is that Ganoderma resinaceum and Pleurotus ostreatus are the fungi of choice,” says Wösten.

Live fungi as intelligent sensors

Maintaining segments of fungal mycelium alive was necessary to use them in sensing and computing applications as part of the vision to develop an intelligent building material. “Mycelium that has been dried and treated is inactive and incapable of functioning as electronic components or reacting to tactile, chemical or optical stimuli with electrical activity,” explains professor of Unconventional Computing Andrew Adamatzky from the University of the West of England, Bristol(opens in new window). FUNGAR uncovered fundamental principles of fungal communication and cognition(opens in new window), identifying evidence of actions like electrical spiking in fungi. The project achieved groundbreaking results in fungal electronics and computing, including the development of fungal sensors and responsive wearables, as well as prototypes of fungal oscillators, capacitors, memristors, and low-pass filters. Several prototypes of fungal computers were conceptualised. “We pioneered the field of fungal electronics and computing, offering an eco-friendly alternative to the current methodologies for electronic device manufacturing, which often have detrimental environmental impacts,” highlights Adamatzky.

Framework for the fungal material

To construct an integrated material, FUNGAR used a triaxial weaving technique called Kagome to produce a stay-in-place mould and surface that can be colonised by the fungus. “The actual weaving of artefacts is haptically complex in terms of material holding and placement, movements to achieve interlacing, and continual adjustments as the weave develops. As a result, automated triaxial weaving is typically limited to the production of planar textiles,” describes professor of Biohybrid Architecture Phil Ayres from the Royal Danish Academy(opens in new window). To tackle this challenge, the project developed a proof-of-concept end effector for an industrial robotic platform with a visual feedback system that allows real-time path modification. Another accomplishment was a digital method to produce principled weave patterns of target geometries. This was tested at a large scale on a weave comprising over 50 000 cells, covering a surface area of around 300 m2. Further research is still required to achieve the monolithic construction of the substrate that the project aimed for. If accomplished outside of laboratory conditions, this will have a significant impact on the construction industry.