Novel 3D-printable high entropy superalloys to withstand extreme heat

The quest for materials that can withstand the extreme conditions of jet engines and gas turbines is at the forefront of aerospace. Nickel-based superalloys, known for their superior strength and resilience at high temperatures, have been a mainstay in these applications over the past decades. However, the demand for higher operational temperatures in the field has pushed their performance to a thermal ceiling, as these temperatures inch closer to the melting point of these alloys. Cobalt-based superalloys have recently gained attention as a strong alternative. Thanks to gamma prime precipitates – microscopic, coherent precipitates that form within the crystal structure – that strengthen their structure, these alloys are set to surpass the performance of their nickel-based counterparts under intense heat. Their production, however, is fraught with difficulties.

Combining the best of both worlds

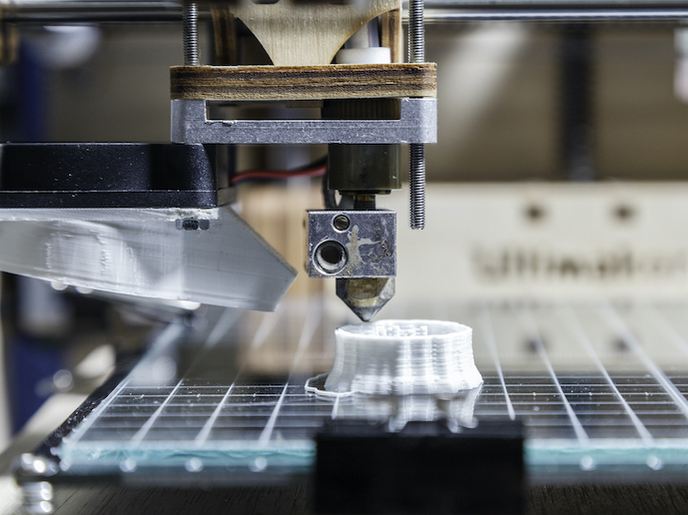

Funded by the Marie Skłodowska-Curie Actions programme(opens in new window), the CNSTech project combined the strength of both metal and cobalt through powder metallurgy, which involves mixing, shaping and heating metal powders to form a solid alloy. “We focused on developing a new generation of superalloys, called high-entropy superalloys,” notes project coordinator José Manuel Torralba. The goal has been to make these metals better than current ones used in high heat scenarios. “We looked to tackle some common problems found in these conventional high-entropy superalloys by refining powder-based methods and enhancing how well they work with cutting-edge 3D printing techniques such as laser powder bed fusion,” explains Torralba.

Advances in high-entropy alloy development

Key achievements include formulating single-phase high-entropy alloy powders characterised by elevated gamma prime solvus temperatures – important for determining the melting point of a certain component in a metal mix. Knowing this temperature allows for precise heating and cooling, and ensures that a specific metal achieves outstanding resistance to pressure and heat. Other accomplishments include the establishment of optimised processing maps for defect-free printing (additive manufacturing technology), also effective spark plasma sintering, which involves applying electrical current and pressure to powders to form solid materials (powder metallurgy technology). Studies were also focused on identifying how atom arrangement and distribution within an alloy – configurational entropy – influence the alloy properties. Through collaboration with external partners, the team achieved notable progress in refining processing methodologies and material characterisation analysis.

Exploring a distinct relationship

CNSTech introduced novel alloy designs and powder processing techniques specifically tailored for high-entropy superalloys, significantly advancing current technology. By employing high-entropy principles for alloy design and using advanced manufacturing techniques, CNSTech sought to achieve higher gamma prime solvus temperatures and improved printability compared to traditional superalloys. “Our disruptive approach is underpinned by the hypothesis that linking the high entropy of mixing with the gamma prime solvus temperature can lead to remarkable improvements,” highlights Torralba. This correlation challenges conventional alloy design strategies, potentially enabling the development of materials with exceptional properties. The impact is considerable for aerospace components and power generation systems, where materials must withstand extreme temperatures and stresses during operation.

Project impact

CNSTech impact is multifaceted. “By linking the high entropy of mixing with improved superalloy performance, CNSTech opens up new avenues of research across various alloy families beyond those initially considered. For instance, applying similar concepts to different kind of steel extends well beyond traditional high-entropy alloys based on multiple principal elements,” states Torralba. This approach advances materials science by deepening understanding of high-entropy superalloy thermodynamics and its practical implications in alloy design. Ultimately, it promises to boost the performance and efficiency of aerospace engines and power generation systems through the development of novel high-entropy superalloys with superior properties.