Turning CO2 into eco-friendly jet fuel for cleaner skies

Aviation is one of the most challenging sectors to decarbonise, especially for long-distance flights where batteries and hydrogen are not yet practical. Airlines and fuel suppliers are increasingly looking to sustainable aviation fuel (SAF) to meet climate targets as it can be used in existing aircraft engines and infrastructure – but with a much smaller ecological footprint than conventional kerosene. Airlines have pledged to fly on 100 % SAF by 2050, and major companies have committed to using at least 10 % by 2030. In addition, the EU’s ReFuelEU Aviation regulation will progressively mandate SAF uptake, making large-scale production a strategic necessity. With this in mind, EU-funded researchers are developing new, cleaner and more sustainable ways to produce SAF in sufficient quantities to meet future needs.

Cleaner fuel feedstocks

Today, most SAF is produced through the hydrotreated esters and fatty acids (HEFA) method – a refining process that converts vegetable oils, used cooking oils, animal fats or other lipid-rich wastes into a fuel that is chemically almost identical to conventional jet kerosene. The drawback is that supply of waste oils is limited, costly and often imported with over half coming from China and Malaysia. The EU-funded GAFT project, supported by the European Innovation Council, has developed a completely different method for producing aviation fuel feedstock using CO2, water, and renewable electricity. Marien de Jonge is the Chief Scientific Officer and one of the co-founders of GAFT, the Dutch company of the same name that leads this research. He explains that the goal of the project was to “develop new ways to produce biofuels and e-fuels that can be used to make SAF, mainly by creating locally produced long-chain lipid feedstocks suitable for the HEFA process.” Instead of depending on used cooking oil, however, GAFT’s clean microbial lipid feedstock will be produced through a unique process combining electrochemistry and fermentation.

A new biological and electrochemical route to SAF

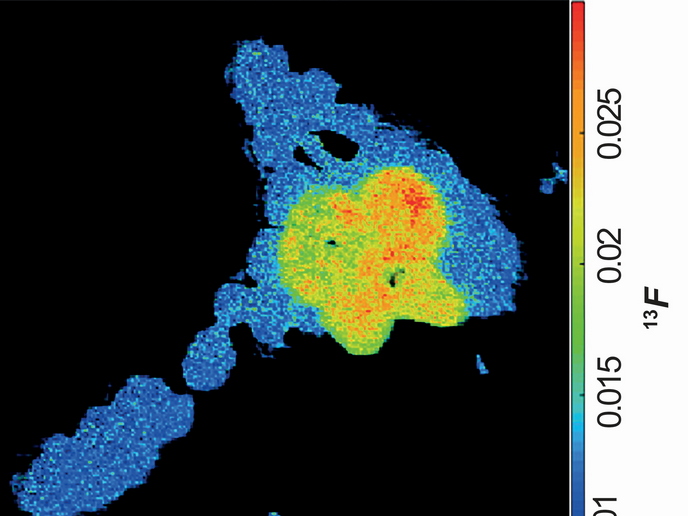

CO2, water and electricity are used in a patented process to produce potassium formate, which is then converted into formic acid. At the same time, a non-GMO microorganism capable of fermenting various feedstocks is used to produce lipids, including triglycerides, which are key precursors for aviation fuel. “Together, these technologies help create a pathway in which renewable electricity and captured CO2 are transformed into the essential building blocks for sustainable aviation fuel,” said de Jonge.

Toward scalable, local fuel production

One of the main advantages of the GAFT approach is the ability to replace imported waste oils with local, renewable feedstocks. De Jonge emphasises that this opens the door to “a more scalable and domestic SAF supply chain,” helping the industry move beyond its dependence on limited HEFA inputs. The process also produces a valuable by-product. The remaining biomass is a protein-rich material that can be used as an ingredient in aquafeed, providing a valuable and sustainable alternative to traditional fishmeal or soy-based feeds.

Looking ahead

Scaling up remains the biggest challenge, as well as securing investment. Negotiations are, however, progressing and the long-term ambition is clear. “GAFT aims to establish a fully scalable, circular, and sustainable supply chain for SAF that relies on locally produced microbial lipids and renewable electricity rather than limited, imported feedstocks like used cooking oil,” stated de Jonge. If successful, the technology could expand SAF production, cut emissions and reduce aviation’s reliance on fossil fuels. And although the road ahead includes engineering, investment and regulatory challenges, the GAFT team believes their model points towards a more resilient future for aviation fuel production.