Plasma technology produces better barriers

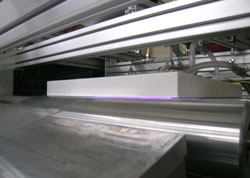

Packaging is a multi-billion euro industry and its value is forecast to continue to rise. It is partly driven by demographic changes with the consumer increasingly demanding safe, yet convenient, well-prepared food. Added catalysts to development are changing legal stipulations for labelling and product technology changes. Consequently, the properties of packaging must satisfy some very demanding criteria. As well as protecting the item inside, packaging must be low cost, have an acceptable production speed and possess adhesion and printability properties for labelling. SOLPLAS, a European funded project has undergone research into coatings designed for plastic films for food and sensitive electronic devices. With regard to food, low permeability to water and oxygen and anti-microbial properties are particularly important. Project partners harnessed a combination of technologies in order to achieve the required product. Scientists at Vito in Belgium, the Flemish Institute for Research, amalgamated aerosol and atmospheric plasma technologies on various hybrid sol-gel precursors. The result was a coating that was superior to the film produced by wet-chemical coating with traditional curing methods. It was ten times less thick - up to three microns only. Not only that, but the oxygen migration performance was more than ten times superior for some of the sol-gel systems under observation. The improved barrier properties together with the faster curing rate for the material are due to two main factors. First, the high surface area of the sol that is atomised and secondly, the plasma environment that is highly reactive. These features combined result in more cross-linking which leads to the desired novel properties of the film. Project partners include manufacturing companies and academic institutions. Potential applications from this innovation are multi-purpose given the range of products that require packaging. This can undoubtedly help to improve the competitiveness of SMEs as well as the larger European manufacturers.