New platforms for bioprocessing

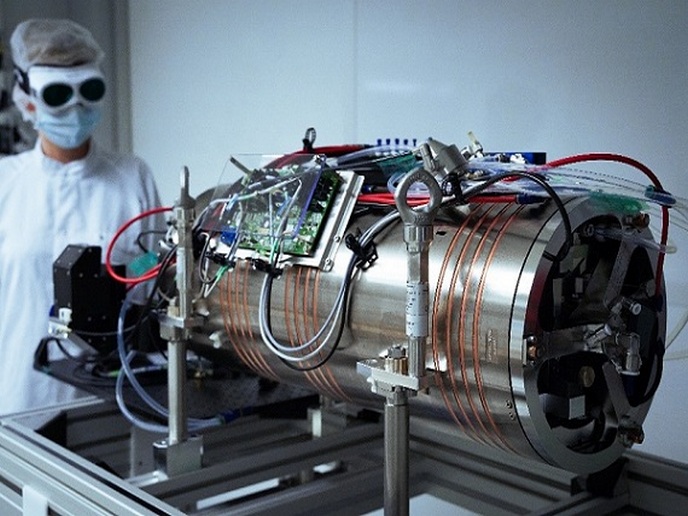

Platform technologies currently being used in the production process of biopolymers with therapeutic interest (i.e. biopharmaceuticals) don't have the required levels of throughput and cannot deliver cost-effective, variable performance with limited disposability. Two examples are chromatography, which analyses complex mixtures by separating them into the chemicals they were originally made from, and electrophoresis, which uses electric force to separate molecules for biological study. By using novel materials and techniques and applying plastic microcapillaries to the separation and purification of biopolymers, research has shown that new platforms can offer high accuracy and reliability with drastically reduced instrumentation costs. Such platforms will greatly enhance productivity in related fields and open up new markets for capillary instrumentation. The 'Separation and purification of biopolymers and biopharmaceuticals using advanced chemical engineering tools' (Plasticbiopharmapur) project aimed to develop advanced tools for more durable, low-cost separation and purification, and for biopharmaceutical production. A recently invented semi-disposable, high-throughput, non-porous micro-engineered material would make this possible. Scientific and technological developments resulted in the delivery of three devices for intensifying chromatographic, electrophoretic and inactivation processes — all relevant to bioprocessing and the healthcare market sectors. The chromatography and electrophoresis devices that were developed are both scalable and offer real-time information of the bioseparation processes. The third device works to inactivate viruses in concentrated protein solutions. Plasticbiopharmapur experiments revealed that a good degree of inactivation of a large enveloped virus could be achieved in about 2 seconds, as compared to the more than 15 seconds normally required in competing inactivation technologies. Research in this EU-funded project led to the development of a new microscale platform for rapid detection of multiple analytes within biological samples using an enzyme-linked immunosorbent assay concept. This has implications for a wide range of applications: environmental control, forensic analysis and clinical diagnostics. Various biopharmaceutical companies have shown an interest in these new technology concepts, and a patent has since been secured for some of the steps critical to the production and use of the new immunoassay platform.