Glass and ceramic design comes of age

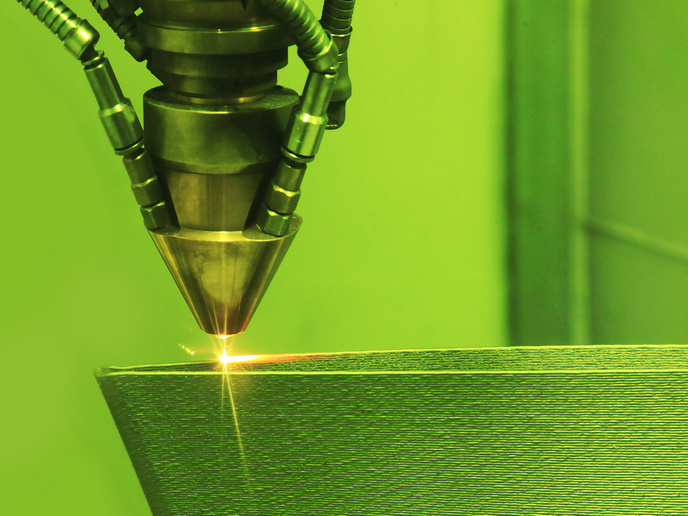

In the fast-paced world of construction and interior design, low costs and production speed are important considerations to ensure viable projects that are delivered on time. The project 'Mass customisation of the ceramic and glass decoration. A contribution to the future manufacturing industries' (Custocer) developed laser technology that enables the customised production of glass and ceramic tiles. The project team studied different laser decorating techniques, chiefly for deposition and activation. It analysed materials, adapted laser technology and developed Internet-based software based on Web2.0 technology that allows clients to design their own products online. The astounding success of the system during initial trials prompted small and medium-sized enterprises (SMEs) involved in the project to patent the two techniques developed. These were the laser fusion technique using a high-powered laser scanning system (HPLSS) and a decorative laser cladding technique with two high-powered lasers. Both involved powder pigments of different colours that could be applied to the surfaces, although the decorative laser cladding technique proved to be more cost efficient and industrially viable. The CO2 laser involved was also able to create reliefs on surfaces, adding more design features and flexibility. Ultimately, this technology has the potential to provide cost-effective solutions to designing and manufacturing tile, glass and ceramic surfaces, making the industry in Europe more innovative and competitive. Its exploitation will bring many rewards to the construction sector.