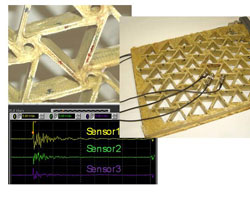

Honeycomb structures for smart materials

Honeycomb sandwich material is commonly used in naval and aerospace construction industries, as well as electromagnetic shield applications. The 'Chiral smart honeycomb' (Chismacomb) project aimed to produce sandwich components with varying complex shapes that incorporate self-health monitoring functionalities. Electromagnetic compatibility characteristics for microwave absorption were also included in the ambitious programme. The key to this extraordinary technology is the chiral honeycomb. Novel materials will exhibit a so-called negative Poisson’s ration and, for example, expand laterally when stretched, in contrast to ordinary materials. The basic honeycomb structure can then house different components to result in materials for multifunctional or specifically tailored applications. Exploiting this property, the Chismacomb scientists developed honeycomb models with three, four or six connecting elements. Simulations using these different combinations under pressure from various directions resulted in thickening while the interlocking structures created a high level of stiffness. On increase of external pressure, the materials expanded and a decrease prompted shrinkage. Materials with different configurations as well as an optimised chiral core were evaluated for their mechanical and dielectric (electric field properties). A curved sandwich panel proved stronger and less prone to the impact of stresses and in-plane buckling than existing materials. Embedding lead zirconate titanate (PZT), an electroceramic material, for custom-designed sensors lends the honeycomb base a structural health monitoring function. When pressure is applied to sandwich honeycomb structures, they will change shape and mould to give optimum passenger comfort. Furthermore, the advanced ergonomics of the material will increase safety in moving vehicles. applications of the Chismacomb technology bulk out the already far-reaching potential of honeycomb sandwich materials. Custom-designed sensors provide material able to monitor its own strength and stability to increase safety for passengers in turbulent conditions such as ships and planes. For improvement of security and health, absorption of microwaves over a given range of frequencies promises to decrease electromagnetic pollution now all too common from transmitters, aerials and overhead power lines.