Batteries to power next-generation vehicles

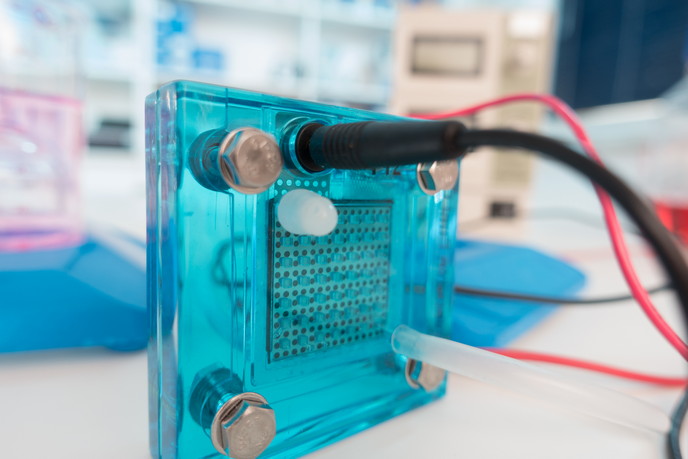

Li-polymer batteries are a family of rechargeable batteries with high energy density, stability and safety characteristics compared to conventional nickel–cadmium batteries. Unlike the classical lithium–ion (Li-ion) battery that uses a liquid electrolyte (charge-carrying or conducting medium), the Li-polymer battery uses a polymer electrolyte. This is typically a solid polymer in the form of a very thin membrane that facilitates ion exchange. Given that they are safer, lighter, flexible and very thin, Li-polymer batteries are gaining renewed interest as an alternative to Li-ion batteries. However, improvements are required to enhance market penetration. Scientists initiated the SOMABAT(opens in new window) project to develop materials and processing methods that meet the challenges of such a goal. The focus was on adequate energy density, lifetime and safety while being low-cost and up to 50 % recyclable. Scientists synthesised plasticised solid polymer electrolytic membranes with porous architectures based on vinylidene fluoride-hexafluoro propylene. Focus was placed on carbon-based anode materials with carbon xerogel additives to improve anode stability. The consortium achieved cost reduction of the Li iron phosphate (LFP) material for use in the cathode. Li iron phosphate–manganese that has higher energy density compared to LFP was also synthesised. Team members investigated the scalability of the novel synthetic and recyclable materials, stacking electrode/membrane pouch cells, large-format automotive cells and smaller pouch cells. A management system for lithium battery packs was able to monitor the pack parameters with precision up to a single cell. Furthermore, it was able to manage and monitor charge and discharge, and ensure safe exploitation. The developed cells and the battery management system were assembled to produce the final battery pack. Project partners have tested recyclability of the developed battery and performed a life-cycle analysis. SOMABAT demonstrated the feasibility of using recyclable and synthetic materials for Li-polymer battery components. Project dissemination activities included presentations, posters, press releases, conferences and workshops.