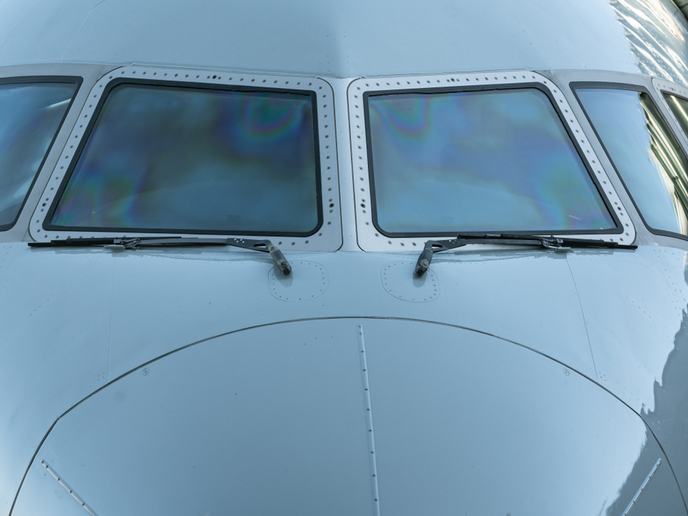

Modelling dynamic loading of aircraft

Current design standards based on conservative static loading often lead to additional and unnecessary weight. Without adequate understanding and consideration of dynamic loads, resulting designs may even be unsafe. The 'Dynamics in aircraft engineering design and analysis for light optimized structures' (DAEDALOS)(opens in new window) project has characterised dynamic loads during aircraft service. Incorporation of effects of material damping, dynamic buckling and mechanical hysteresis stand to remove the uncertainty and conservatism of present-day aircraft certification procedures. Conventional design practice considers the fuselage as a beam on which a load is statically applied. It is a highly simplified model assuming that no energy is absorbed from the fuselage by the stringer/frame/skin constructions. It assumes that the full load propagates along the fuselage without attenuation from structural damping. This is not the case in the real system. In addition, dynamic buckling can be much greater than static buckling, meaning that the fuselage could theoretically absorb more energy without breaking under a higher load than is predicted in the static case. The end result of these assumptions is a heavier design that may not address real-life dynamic loading conditions. DAEDALOS developed a mid-size business jet model for the analysis. The team developed full finite element and hybrid models at various scales. Various methods for evaluating structural energy dissipation via damping were developed and implemented. These included a strain energy method, as well as quasi-linear viscoelastic material and generalised Maxwell viscous material damping models. A rigorous campaign of experimental testing supported model development. The team evaluated materials damping of an aluminium alloy and two carbon-epoxy composites at coupon level using a variety of techniques. Panels and shells representative of typical components were also tested subjected to static and dynamic loads. Furthermore, the components were assessed in terms of weight benefits. Through its advanced models, simulation tools and databases, the DAEDALOS project established a scientific basis for new aircraft design and certification standards reflecting energy dissipation during dynamic loading. Dynamic analysis is part of the design process in many industries and DAEDALOS deliverables could therefore be appropriate in a wide range of applications and fields.