Big benefits for the polymer industry

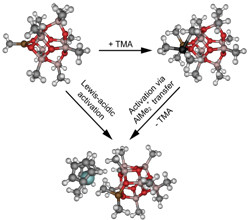

Polyolefin-based polymers include polyethylene and polypropylene, used in products from plastic bags and packaging to electrical insulation, cars, furniture and medical devices. The goal of the project 'Methylaluminoxane (MAO) activators in the molecular polyolefin factory' (MAO-ROBOTS)(opens in new window) was to create novel optimised MAO building blocks to decrease polymer production costs with sustainable methods. To achieve this ambitious aim, EU scientists focused on enhancing understanding of molecular and supramolecular assembly and construction principles. MAO-ROBOTS applied an unprecedented combination of chemical, spectroscopic, neutron-scattering and computational techniques. Work led to beyond state-of-the-art control of MAO-activated polymerisation processes. Even better, the team delivered an ethylisobutylaluminoxane, a more economical and environmentally friendly alternative, able to polymerise ethylene equally as well as the best MAO. Work began with development of a continuous liquid-phase reactor set-up for MAO synthesis. It allowed better control of product characteristics given the slow equilibration of MAO solutions. A model enabled screening of synthesis reactions by determination of the structure of the resulting MAO in silico. In combination, the experimental and computational studies revealed the detailed cage-like structure of MAO species. Investigators also shed important light on the mechanisms of catalytic activation of MAO for polymerisation processes. MAO mixtures contain a variable amount of associated trimethylaluminium (TMA). Scientists found evidence that it generates the sites of co-catalytic activity, and determined a quantitative relationship between polymer molecular weight and the TMA content of MAO. Further, the team detected two possible modes of MAO activation of single-site olefin polymerisation catalysts. Actually, these catalysts show the highest market growth rate. Researchers developed an important rapid screening method for catalysts and catalyst activators like MAO that should expedite development. MAO is an important activator of the polymerisation process leading to industrial production of polyolefins. MAO-ROBOTS outcomes have the potential to save the polymer industry millions in production costs annually, and could substantially reduce environmental and safety risks involved in polyolefin production. Taken together, the project is expected to strengthen the EU polymer industry with important benefits for workers and the environment.