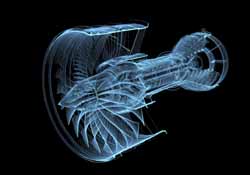

Improving aero-engine performance

Although aircraft turbines have evolved tremendously in recent years, the lubrication systems that remove heat and lubricate the highly loaded parts have remained largely unchanged. To meet future requirements, including improved thermal efficiency and lower specific fuel consumption (SFC) while maintaining reliability and lower mass, novel technologies are needed. The EU-funded project 'Engine lubrication system technologies' (ELUBSYS)(opens in new window) addressed this challenge using novel seal technologies such as brush seals. Brush seals reduce bleed air losses while withstanding the harsh aircraft engine environment, thus improving engine propulsive efficiency. Their aim was a 60 % reduction in bleed air and engine oil consumption, improved oil quality monitoring, improved thermal management and reduced lubrication system mass. The technology will have fundamental impact on reducing SFC and emissions. Team members evaluated three types of brush seals, including Kevlar and carbon. Their ability to seal a bearing chamber with reduced requirements for bleed air as well as endurance under extreme conditions were assessed. These seals outperformed expectations with a reduction in air consumption ranging from 75–95 % and excellent endurance. Scientists also studied the impact of the brush seals on thermal efficiency and oil quality. This was accomplished by considering the entire lubrication system, including scavenge and vent port performance and oil behaviour. Detailed experimental investigations combined with numerical models led to a set of design rules and guidelines for better lubrication systems in modern gas turbine engines. Several different types of oil health sensors were developed. Two of these have already been validated in the harsh engine service conditions to which they will be subjected. Overall, ELUBSYS technologies could reduce engine mass by up to 26 kg, oil consumption by up to 60 % and air consumption by 90 %. In addition, they are likely to significantly reduce maintenance costs and direct operating costs while reducing its impact on global climate change. Improvements in existing engines and oil equipment as well as recommendations for future designs will have considerable impact on the competitiveness of the EU aerospace industry.