Piezoelectricity, charged with possibility

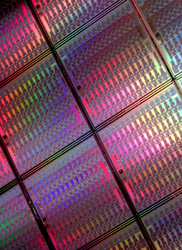

Piezoelectricity is the electric charge which accumulates in a solid as a result of applied mechanical stress. This effect is also reversible. Piezoelectricity can be used to produce and detect sound and generate high voltages; it is also useful in precision applications such as microbalances and the ultra-fine focusing of optical assemblies. To exploit piezoelectricity's enormous potential, the 'High volume piezoelectric thin film production process for microsystems' (PIEZOVOLUME) project developed an integrated, high-volume production process for piezoelectric microsystems. With funding from the EU's Seventh Framework Programme, the project developed a micro-fabrication platform covering the entire production process chain. PIEZOVOLUME focused in particular on the three most significant hardware and software bottlenecks hindering the mass production of piezomicro-electromechanical systems (piezoMEMS). To facilitate and accelerate the commercialisation of the project's results, partners grouped together technology providers and users with large, small and medium-sized enterprises. The project developed specific tools and processes for the large-scale manufacturing of piezoMEMS, plus the formulation of manufacturing rules and guidelines, especially for piezoelectric lead zirconate titanate (PZT) thin films. PIEZOVOLUME also developed, tested and validated a number of technologies that would make this possible, including a double-beam laser interferometer system for up to 8-inch wafer characterisation. The PIEZOVOLUME system will enable manufacturers to develop production processes for a broad range of products. These include inkjet printing heads, active optic elements such as autofocusing lenses and scanners, and ultrasound transducers for proximity sensors and even for medical imaging at high frequencies. It will also strengthen Europe's competitiveness in the supply of core production machinery for the production of piezoelectric films.