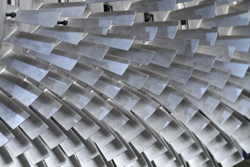

Superalloys equal stronger, greener turbines

Turbines are used in aerospace engines, energy plants and other industrial installations. In these large-scale applications, lowering the weight of components brings big gains in terms of energy efficiency. However, they also have to be resistant to extremes of temperature, moisture and force. Researchers are designing hybrid silicide-based structures that can meet the demand for lower-weight components without sacrificing durability. Working together through the EU-funded 'Hybrid silicide-based lightweight components for turbine and energy applications' (HYSOP) project, the international team is looking into making components with tailored microstructures and properties. The composite materials they are focusing on — Nb/Nb5Si3 and SiN4/MoSi2 — are able to operate at above 1 300 degrees Celsius and show amazingly high strength. But the challenge is to develop coatings that can improve their oxidation resistance. The team has been testing various coating systems under high temperatures and environmental conditions. Drawn from science institutes and industry from around Europe, the researchers are developing innovative manufacturing systems based on powder milling techniques, net-shape Hot Isostatic Pressing (HIP), powder injection moulding and laser fabrication. Two conflicting trends mean significant improvements in energy efficiency are a must — the global demand for energy is ever-increasing, whilst the potential for catastrophic climate change calls for dramatic cuts in carbon dioxide (CO2) emission. These cutting-edge materials stand to be an integral part of the solution.