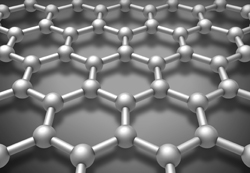

Mass production of carbon nanotubes

Thanks to their unique mechanical, surface and thermal properties, CNTs have great potential for use in revolutionary products that use microwaves and X-rays. However, because of the lack of viable mass production technologies they have yet to find their way into mainstream production. The EU-funded 'Technology for wafer-scale carbon nanotube applications' (TECHNOTUBES) project set out to resolve this. Researchers developed equipment to produce large wafer-scale CNTs and find specific areas of applications for them. For instance, high-current-density field emission electron guns can be used in X-ray imaging systems for health care and luggage scanners. High-sensitivity, low-power and low-cost sensors would be ideal for metal-oxide-semiconductor (MOS) electronics and hot plates; and microfluidic devices for chromatographic applications. With a team drawn from leading manufacturers and research institutes from several countries, the project created a full development chain: from nanotube growth, to the materials and processes needed, to the prototyping methods and applications to use them. The 12 inch wafer production system consists of a three-zone graphite wafer heater for uniform temperature, top-side remote plasma system and a showerhead gas distribution. There is a separate device for batch-loading wafers preheated up to 400 degrees Celsius. This machine produces a wafer every 30 minutes, costing only EUR 21 per wafer when capital costs are spread over 10 years. This price is seven times below the team's original target. TECHNOTUBES partners successfully produced a prototype for high density field emission electron guns using CNT for use in X-ray sources for luggage scanners. They also produced sensors for complementary MOS electronics and hot plates, meeting all required specifications. Project outcomes will ensure a continued market-leading position for European firms in this area, with a potential for exponential growth in the next few years. The innovative system will enable many previously impossible applications in the use of X-rays or gas sensors in hand-held devices.