Tools for better manufacturing processes

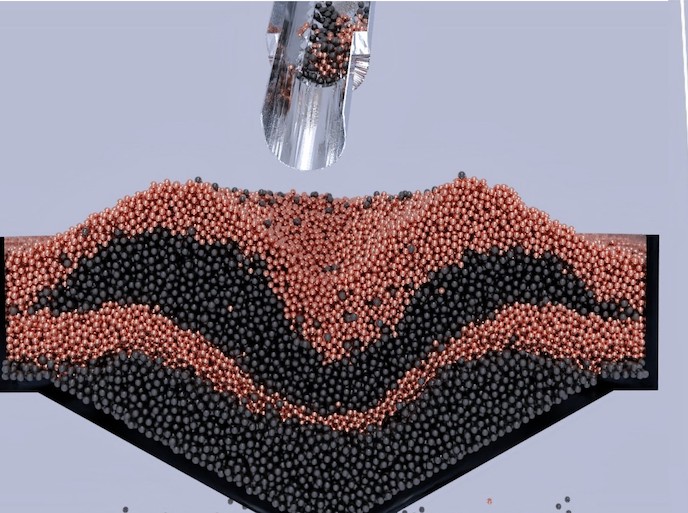

Modern manufacturing is incredibly complex, because process engineers need to consider a vast array of variables and options. Unfortunately, current planning tools focus on individual processes rather than taking a holistic approach, and they are not flexible enough for modern manufacturing demands. A unified process planning tool for manufacturing, developed by the EU-funded project ENEPLAN(opens in new window) (Energy efficient process planning system) addressed this problem. The tool produces flexible but well-adapted processes for any given manufacturing process or product. It will also be designed to unite and function across multiple processes and even multiple companies. Researchers opted for a modular software approach that incorporates modules for data assessment, intelligent monitoring, predicting economic demand and process simulation into a holistic tool. ENEPLAN created monitoring systems and a market needs model to form part of this system, which they call the Meta-CAM tool. They also chose three business cases, one from each of the automotive, aeronautics and household industries, for prototype testing. Early tests were successful, with the tool identifying a major source of inefficiency in these industries. Researchers also created alternative production plans and used them to evaluate the new tool. Finally, ENEPLAN has completed detailed plans for bringing this new technology to market. The tool will be implemented from product concept to customer shipping. It is set to decrease the environmental footprint of different processes while also improving energy efficiency.