Applications drive tool engineering

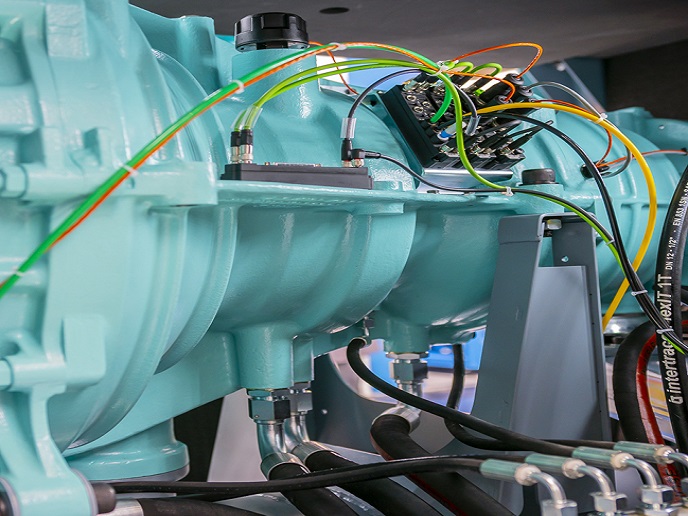

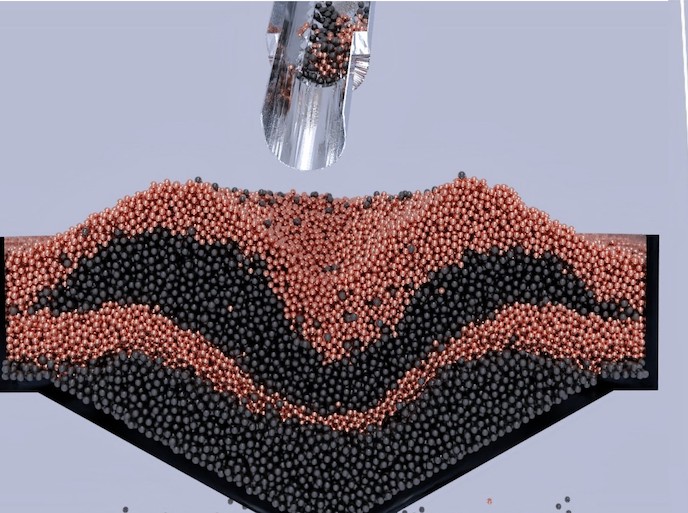

An accelerated pace of development in aircraft and automotive sectors opens up new possibilities for component concepts based on materials such as superalloys and super-hard steels. As part of the process of updating their production line, manufacturers overhaul machining processes used to produce demonstrator parts. In 2011, the EU-funded project QUICKPRO(opens in new window) (Quick process and tool design for advanced multi-axis milling of hard-to-machine materials) was initiated. The aim of QUICKPRO was to research the selection of the most appropriate tools for diverse machining tasks and draw qualified conclusions. QUICKPRO partners focused on cutting tools for drilling, turning and milling exposed to high thermal and mechanical loads when used on difficult-to-cut materials. These extreme conditions often result in short tool lifetimes, long processing times and poor-quality of the workpiece surfaces. Determining the optimum conditions for cutting tools is pivotal, particularly with regard to the tools' substrate material and coatings. QUICKPRO partners looked into technological advances related to the macro- and micro-geometry of tool cutting edges and tool coatings, as well as process parameters and milling strategies. Tools were tested on a test bench adapted to evaluate the tool-material-machining parameters. The quality and adhesion of the coatings to the tool substrate were assessed at various temperatures in impact tests conducted at a second, specially developed testing facility. Following testing, QUICKPRO partners worked on the design of machining strategies for milling complex geometries. Unfavourable tool engagement conditions were avoided to achieve tool paths that result in longer tool lifetime and enhanced part surface quality. The outcome of the QUICKPRO project is a standardised procedure for drawing up specifications for the tool-material-machining parameters system. The time required to develop cutting strategies will be significantly reduced by adopting this approach. The previously untapped potential of the multi-axis machining process can now be exploited, significantly increasing the productivity of small businesses and helping them meet customer demands.