Novel welding process for Europe's shipbuilding industry

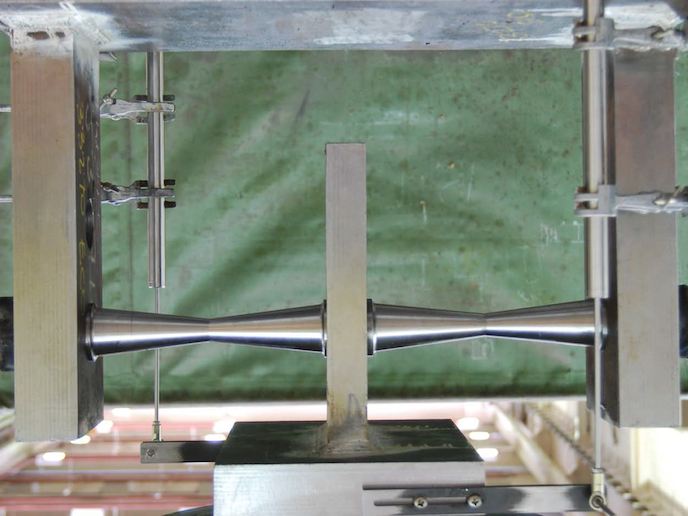

Is friction stir welding (FSW) capable of welding all grades of steel used in the shipbuilding industry? The EU-funded HILDA (High integrity low distortion assembly) project sought to find out by developing this welding technique for steel. Project partners developed a cost-effective, low distortion welding procedure for shipyards to efficiently produce lightweight ship structures. Ultimately, innovative steels and the welding of different steel grades will be used for butt and fillet welds in a very precise manner. The HILDA team advanced knowledge in forecasting the complex phase modifications, heat changes and subsequent internal stresses that take place during FSW. It used real-world FSW data of high-strength low-alloy steel to develop a thermo-mechanical computer model and defined the process parameters to join steel with various sheet thicknesses. This allows FSW technology that is widely used in aluminium construction for the aerospace and rail sector to be transferred to steel shipbuilding. Using project outcomes as a basis, researchers developed and validated an expert system with accompanying software for use in industrial settings. Shipyards can use the system to optimise ship construction in line with accuracy requirements. Lastly, the costs and benefits of steel FSW in its current immature state were compared with the costs of existing fusion welding techniques in steel. The opportunities for cost reduction, safety improvement and enhanced weld properties that friction stir welding should provide were also identified. Potential disadvantages were also noted, namely tooling-related issues that emerged during the project which need to be addressed in the future. HILDA demonstrated the feasibility of FSW as an innovative joining technique for steel panels and components. With some further tweaks, the technology will be brought closer to industrial application.