Plastics and nanotechnology

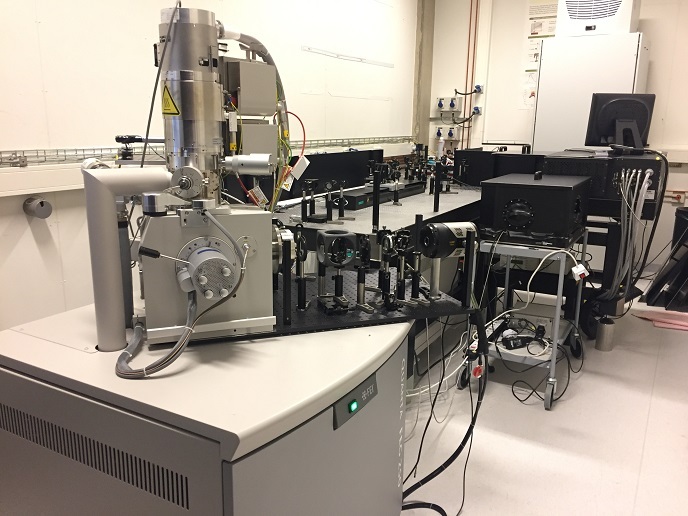

Nanoscale devices offer great potential, yet remain difficult and expensive to make. Integration of plastics into the device structure as components shows promise for many applications, but such work remains in the early stages. The EU-funded SMONDEP (Scalable manufacturing of organic nano devices for electronics and photonics) project developed new methods for fabrication of organic compounds. The work helped advance the integration of plastics into new photonic devices, and to demonstrate nano-manufacturing's economic viability and scalability. Project research focused on chemical vapour deposition (CVD) and a pattern transfer method based on silicon nanomembrane (SiNM) technology. The purpose was to develop new nano-manufacturing methods compatible with conventional semiconductor manufacturing. The team designed and built several electronic and photonic device components using the CVD method. The list includes passive waveguides, optical gratings, photonic crystals and microlens arrays. For each component, researchers also conducted extensive testing and characterisation. Results indicate that polymeric nanostructures and thin coatings can be made on flat 20x20 cm substrates, with thickness variation less than 5 nm. Deposition rate can be finely tuned. In addition, the CVD system can be modified to use flexible substrates compatible with roll processing. A roll-to-roll CVD system with a substrate width of 1 m would be feasible. Such a system could be easily scaled up to incorporate a 1x1 m substrate with no cost increase. The team concluded that roll-to-roll fabrication is more suitable for large-area applications such as coatings, otherwise a batch system would be appropriate. The SiNM process provided an effective and cheap alternative to conventional lithographic methods. However, the method was only applicable for small batch-size CVD systems. The method could not be transferred to large-area substrates or roll-to-roll systems without significant costs. Therefore, the method was deemed not economically feasible. SMONDEP's new methods for manufacturing nanodevices are important steps towards an economically viable process. The work has helped progress the integration of plastics into nanotechnologies.