Better performing carbon fibres at reduced cost to profit and planet

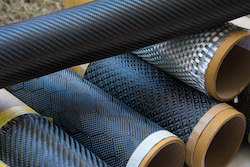

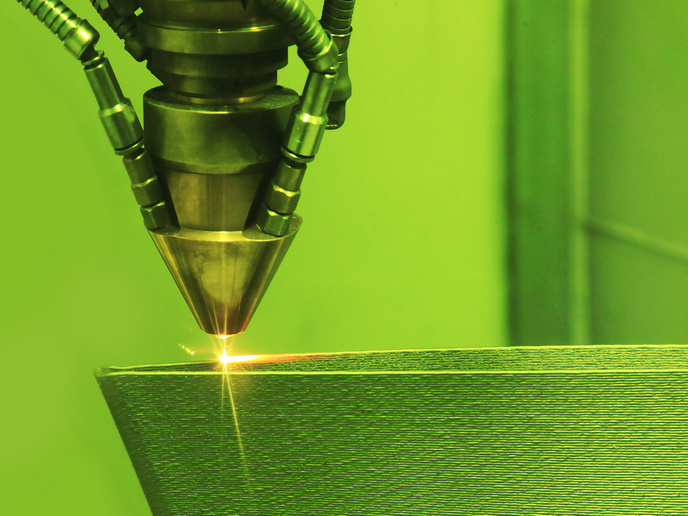

Despite being typically only 5–10 micrometres in diameter, carbon fibres (CFs) have many desirable properties such as high stiffness and strength, coupled with low weight and high tolerance to temperatures. This makes them of interest to the aerospace, civil engineering and military industries. However, CFs remain expensive when compared to alternatives and the manufacturing process comes with significant challenges including the fact that the polymer resin, polyacrylonitrile (PAN), used as the precursor in 90% of carbon fibres, raises safety and environmental concerns. The EU-funded NEWSPEC (New cost-effective and sustainable polyethylene based carbon fibres for volume market applications) project explored the properties of polyethylene (PE) as a precursor for low cost CF production. The team designed, developed and tested working prototypes for continuous CFs processing which included: melt-spinning equipment capable of semi-industrial manufacturing of PE fibres, gas phase sulfurisation equipment, double-spot plasma equipment for CF surface functionalisation and a remote Raman probe for in-line monitoring of the CF’s mechanical features. Introducing innovative processing techniques Explaining NEWSPEC’s interest in exploring PE as a carbon fibre precursor, NEWSPEC project coordinator at Warrant Group EFD(opens in new window) Dr Matteo Falasconi says, “It presents interesting technical features such as a high carbon yield and suitability to produce medium performance carbon fibres. It is also relatively flexible and easy to process at a very competitive cost of around two euros per kilogram. Compared to PAN that is a precursor cost saving of up to 70 %.” After testing, then discounting oil-based and recycled PE, the project found Bio-PE derived from dehydration of bio-ethanol to ethylene – and then polymerisation to PE – offered significant advantages. It is widely available, as a by-product of annual food crops, is of good purity and consumes less energy (about 70 %) compared to petrochemical alternatives. Crucially, it is also sustainable, renewable and ecological, as producing 1kg of Bio-PE captures 2.5 kg of CO2 from the atmosphere. In order to prepare the PE polymers for conversion into CFs, they undergo a process known as stabilisation which strengthens them for high temperature manufacturing. NEWSPEC introduced an original dry method using solid elemental sulphur assisted by Electron Beam Curing (EBC) that introduces heteroatoms at the precursor stage, to replace the usual wet (acidic) process associated with safety and environmental concerns. However, as Dr Falasconi explains, “This innovative gas phase sulfurisation process had never been attempted before on a pilot scale, so our challenge was to design and develop such equipment for PE precursor stabilisation and carbonisation. This we successfully accomplished calling the equipment, ‘SULFI’.” NEWSPEC also reduced graphitisation or the temperature at which the stabilised PE polymer starts to convert into the crystalline carbon structure. It did so by introducing nano-agents (such as cellulose nanocrystals) into the polymer matrix. Additionally, for carbon fibres to become good material composites they undergo a process called surface functionalisation, which is an essential step to improve the compatibility of the fibres with different resins. NEWSPEC used atmospheric plasma technology for this, finding it to be environmentally friendly and flexible (suitable for all types of chemical groups), while being applicable for continuous production from start to finish. Sustainability benefits across multiple industries NEWSPEC applied both Life Cycle Costing (LCC) and Life Cycle Assessment (LCA) to its production and performance innovations. It found strong evidence of reduced environmental damage, with the precursor changes. The LCA also showed the positive effect of introducing atmospheric plasma for surface treatment, leading to a 5 % reduction in environmental impact. As Dr Falasconi summarises, “The polyethylene carbon fibres could provide the highest performance/cost ratio than any other precursor currently under investigation.” Besides the civil and industrial infrastructure sectors, the use of CFs for more efficient wind energy blades, especially in offshore areas, is projected to be the first and largest application sector by 2020. Retrofitting already installed (smaller) turbines is also of considerable interest to energy companies.