New biosurfactants and specialty sugars

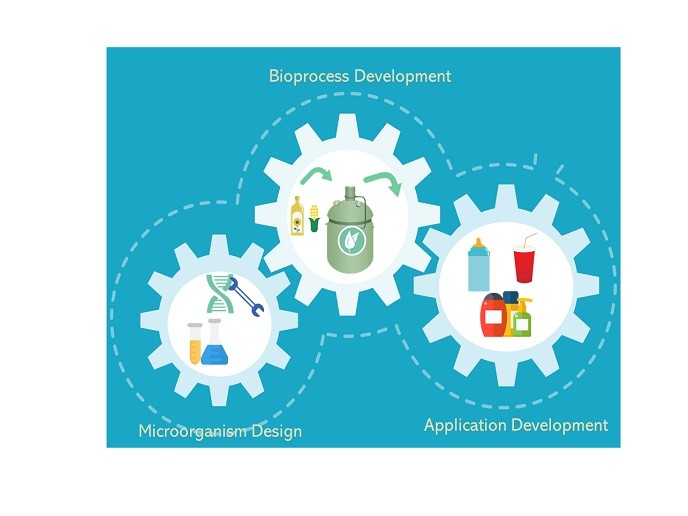

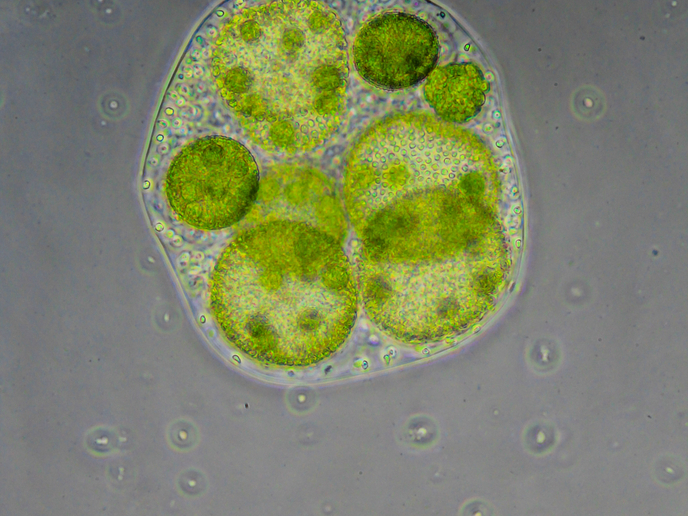

In the bioeconomy, existing industrial biotechnology platforms need to constantly adapt to meet specific market needs. Surfactants are important high-performance molecules, whose worldwide annual production amounts to more than 20 million tons. They are common in various industries such as cosmetics, pharmaceuticals, food products, chemicals, mining, textile and paper and even construction. An emerging class of surfactants are the so-called microbial biosurfactants that are produced solely by microorganisms. The CARBOSURF(opens in new window) project addressed the full exploitation of two very promising types of specialty biochemicals, biochemical compounds that are used for specific applications. These include glycolipid biosurfactants (new types of sophorolipids, rhamnolipids, mannosylerythritol lipids (MELs) and xylolipids) as well as specialty carbohydrates with high market interest. These innovative molecules are being developed in close cooperation with relevant major market players. Discovery of new-to-nature industrial biomolecules CARBOSURF developed new biobased processes for fermentative production of microbial biosurfactants and specialty carbohydrates. The main objectives of the study were the reduction of the development times and time to market and the improved efficacy of these molecules in commercial applications. “We developed new biosurfactant and specialty carbohydrate compounds and showed that we could use agricultural waste products (2G sugars) for their production,” says Prof. Wim Soetaert, CARBOSURF project coordinator. A set of microbial strains efficiently producing new types of glycolipids and specialty carbohydrates was therefore created. 2G sugars are carbohydrates that can be manufactured from various types of non-food and/or waste plant materials and animal waste. The production process of these 2G sugars was adapted so that they could be efficiently converted into biosurfactants by fermentation. The production of these biosurfactants from 2G (non-food) instead of 1G (food) sugars improved the environmental profile. Once new strains became available, the bioprocesses (fermentation and purification) were developed at lab scale and subsequently applied in scaled-up fermentations. “Our team achieved the scale-up of the majority of these new biomolecules,” explains Soetaert. For the new types of sophorolipids (alkyl and bola sophorolipids), xylolipids and sialylated carbohydrates, the processes for promising strains were scaled up to the 100 l scale, giving range to kg amounts of the new product(s), whereas for the rhamnolipids, the production process was debottlenecked at the ton scale. Eco-friendly and cost-effective biosurfactants and specialty sugars in Europe Specific examples of the applications of biosurfactants include the use of xylolipids as biological preservatives in beverages and rhamnolipids for green and mild performers in personal hygiene products. The specialty sugars sialylated carbohydrates can be used in infant formulas, cosmetics and nutraceutical products. Furthermore, the team developed new molecular tools for S. bombicola, S. cerevisiae, E. coli and Pseudozyma bacterial strains to efficiently produce (new-to-nature) sophorolipids, rhamnolipids, xylolipids, MELs and specialty carbohydrates. This knowledge increases the biochemical potential of the strains for the development of future new-to-nature biosurfactants and specialty carbohydrates. Project results obtained so far produced market entry rhamnolipids and ongoing market entry xylolipids and sialylated carbohydrates in Europe. Further activities and research promise new sophorolipids for the market in the near future. Products developed during CARBOSURF will boost economic development and employment in Europe, while having a positive effect on the environment.