The curve appeal of the next generation of biomass condensing boilers

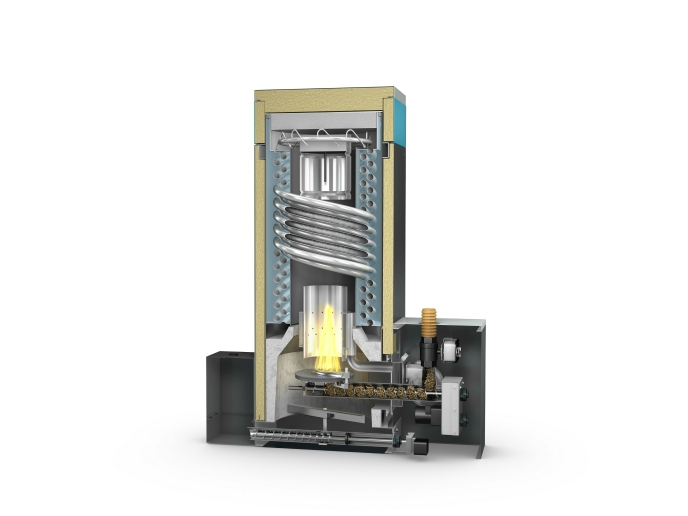

Countries and individuals are seeking to transition to renewable energy sources to relieve dependence on fossil fuels. This trend has helped foster the growing market for heating technologies that exploit the combustion of biomass in the form of wood pellets. However, until now, the market has faced obstacles related to energy efficiency and cost-effectiveness. The EU-funded C-HEAT project addressed these issues and much more. Scientists set out to remove the practical obstacles to adoption of the technology and significantly advance the state of the art through reduced emissions, enhanced reliability, and ‘plug and heat’ integral energy units. Ground-breaking heat exchanger design Until recently, the non-condensing biomass boiler systems had difficulty competing with efficient, condensing boilers utilising fossil fuels. Thanks to game-changing and patented technology by C-HEAT partners BioCurve and Curvados Quintin, this is no longer the case. According to the project coordinator, Ignacio Quilez, the team’s novel optimisation of both the combustion and energy transfer processes resulted in “the first biomass condensing boiler without the need of secondary circuits or external heat recovers. That is, the first biomass boiler that has been capable of using a technology, condensation, which was only available for fossil fuels.” Specifically, researchers developed a novel spiral-shaped biomass heat exchanger that increases the heat-exchange surface area by approximately 50 % compared to standard biomass boilers. The spiral design results in a 5-20 % increase in energy efficiency compared to conventional biomass boilers by harnessing the latent heat of condensation of water vapour in the exhaust stream. This process also leads to reduction of particulate emissions at the exit. A nice side-effect of the spiral design is the simultaneous decrease in volume of the system. Scientists have exploited the technology in a new series of ultra-compact boilers with enhanced thermal outputs of 125, 150, and 200 kW to complement the existing 25 kW and 100 kW boilers. Quilez states, “…the body of the 200 kW BioCurve boiler – the world’s largest biomass condensing boiler – needs only a surface of 1.2 square metres whereas … some of the finest wood pellet - non condensing - boilers need 1.5-1.7 square metres.” Multiple applications with numerous benefits C-HEAT condensing boiler technology for use with wood pellets benefits the end-user, the environment, and potentially, even the local communities where it is used. According to Quilez, an affordable investment rewards end users with a record level of energy savings and a low and stable cost of fuel (wood pellets). In addition, fuel security is improved by relying on locally produced energy sources independent of geopolitical factors affecting fuel availability. C-HEAT’s boilers are appropriate for domestic, tertiary (offices, shops, schools, etc), and small-scale industrial sectors. Thanks to their low-temperature capabilities, they are also suitable for radiant heating under floors or for heating pools. Cultivated forests and carbon neutral technology benefits the environment. In addition, the biomass sector produces jobs, often in rural areas, helping prevent depopulation. Testament to C-HEAT’s commercial potential, Quilez says the biomass condensing boilers for heating are already “…available in seven countries, including those with some of the strictest limits in terms of emissions and efficiency, such as Germany, France, and the Netherlands.”