Robots improve finishing of complex free-form surfaces

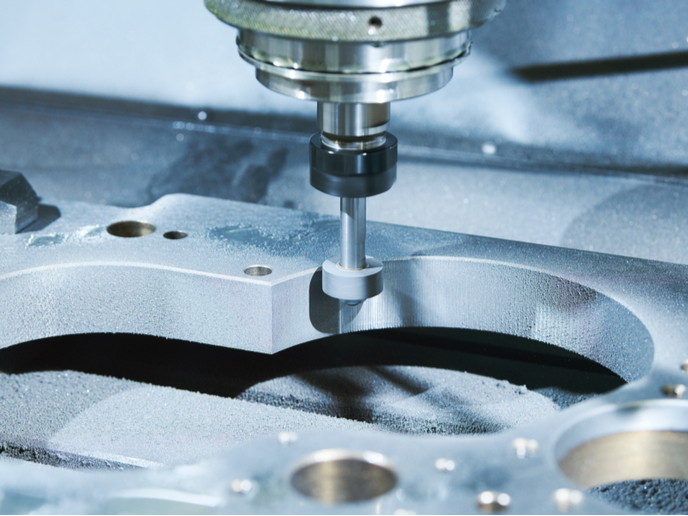

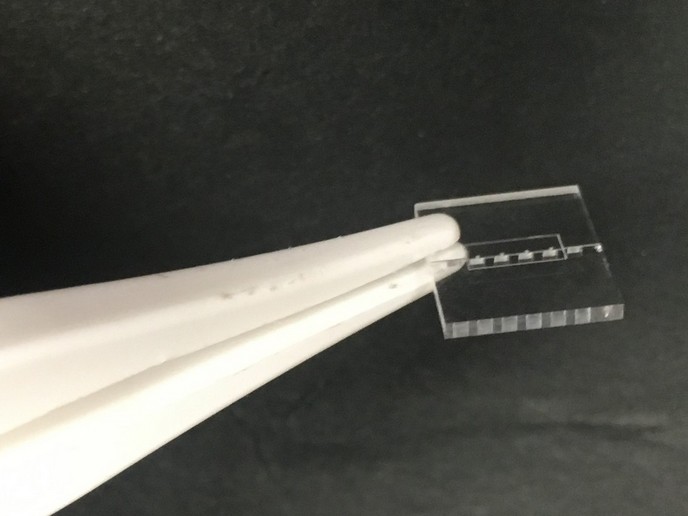

Industrial robots are commonplace. They can quickly do simple, repetitive tasks, even many requiring high precision with high reliability. However, when it comes to finishing complex free-form metal surfaces, manual labour accounts for 90 % of work done today. Over 95 % of the approximately 7 000 companies in the field globally are small- and medium-sized enterprises(opens in new window). European companies are at a disadvantage when it comes to labour-intensive operations due to wage disparity in comparison to countries like China, India, and Brazil. Fifteen teams from academia and industry in five European countries worked under the EU-funded SYMPLEXITY(opens in new window) project to resolve this problem via safe human-robot collaborative systems. Collaborative identification of critical surface features Targeting the mould and die industry, SYMPLEXITY focused on three commonly used finishing techniques: abrasive finishing, fluid-jet polishing, and laser polishing. One of the key difficulties in automating finishing of complex free-form shapes without human eyes and hands is understanding the surface properties of the product before, during, and after processing. To overcome this important barrier, scientists developed sensor and metrology capabilities for automated objective identification of surface properties. Mathematical data employed by the robot in calculations is stored in a database and can be assessed by the human operator as well. For anyone not excited by machining and metrology, SYMPLEXITY is changing the game. Researchers exploited Microsoft’s HoloLens to overlay measured data and parameters on the actual part in 3D via augmented reality. Not only is it fun but it should lead to faster, easier, and more effective decision-making about reworks and defects. Symbiotic human-robot relationships SYMPLEXITY produced both a lightweight and an industrial-grade collaborative robot. The former can autonomously carry out processes such as automated laser polishing, automated surface measurement, and cleaning. Subsequently, it can be used by the operator as a flexible handling system for rework. The second demonstrator introduces the concept of a reconfigurable robot cell. It is based on conventional computer numerical control (CNC), a computer-aided design (CAD) protocol for converting spatial or geometrical designs into numerical representations. To that, SYMPLEXITY integrated technologies for abrasive finishing, fluid jet polishing, and an optical surface measurement system. The robot cell’s modular configuration enables separate finishing processes or complementary use of both. As project coordinator Sebastian Hähnel explains, “Abrasive finishing enables relatively high material removal rates whereas fluid-jet polishing allows a better tool accessibility through less limitations of the tools construction size.” Automated programming of polishing sequences and flexible control of machine parameters such as applied force make a compliant tool holder better at mimicking so-called ‘finger feel.’ Importantly, the robot cell supports machine learning, with both robotic experience and human knowledge as teachers. Autonomous complex surface finishing on the horizon According to Hähnel, “One of the highlights of the project was the opportunity to present the SYMPLEXITY project with the reconfigurable robot cell at Automatica exhibition 2018 in Munich. The concept created a lot of interest and new relationships with customers and potential future project partners.” The SYMPLEXITY solutions are connecting people, data, and machines. The symbiotic human-robot manufacturing tools and quality control systems in one promise to convert 80 % of currently manual polishing work to autonomous robotic control. This will give European mould and die companies a competitive edge over countries depending on a cheaper labour force to keep product prices down.