Once overlooked industrial energy recycling heats up

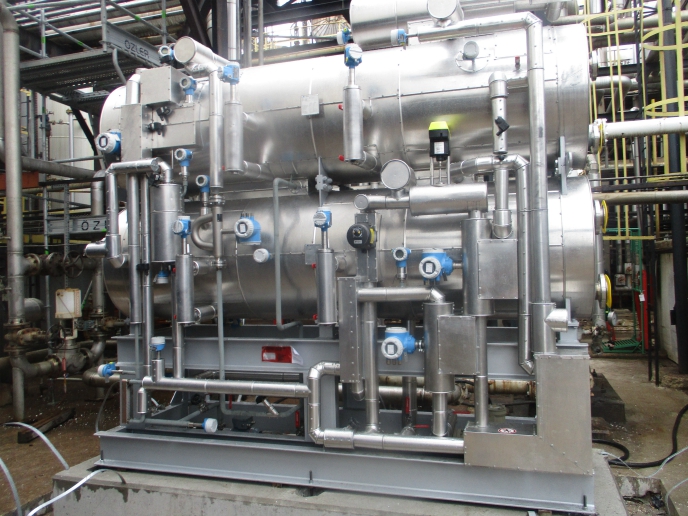

Heat makes up approximately two-thirds of the total energy use in industrial processes(opens in new window). Around one third of industrial energy demand(opens in new window) is dissipated into the environment. Despite these impressive figures, there is insufficient investment in waste-heat recovery technologies. The reason is that most of this wasted energy is of low quality. Capturing low-grade heat for reuse elsewhere on an industrial plant is usually not practical or economically viable with current established technologies. The EU-funded Indus3Es(opens in new window) project has developed a low-cost system that rises to these challenges. Absorption heat transformers (AHT) maximise heat recovery at temperatures below 150 °C. The system was installed and demonstrated in a real industrial environment, in Turkey-based petrochemical company Tüpraş. This is one of the firsts AHT deployments in Europe in last years.

Waste heat recovery now viable for low temperatures

The key to making waste heat recovery technically and economically feasible is understanding the nature of the energy involved. The temperature distribution of waste heat depends on the type of industry. Overall, a large portion of waste heat has a temperature below 200 °C in most industries. Yet, economically viable heat recovery and revalorisation technologies have been limited primarily to medium-to-high-temperature waste-heat sources. “The AHT developed within Indus3Es effectively recovers and revalues low-temperature waste heat at competitive costs. Using a waste steam of around 100 °C, it produces a higher-temperature stream, becoming reusable in refinery operations. Overall, it leverages about 50 % of low-temperature heat that would otherwise be discharged to the atmosphere,” notes project researcher Asier Martinez-Urrutia.

General working principles

AHT have operation cycles opposite to those of absorption chillers, which use heat to generate cooling. Both consist of a condenser, an evaporator, an absorber and a generator. The difference is that the absorber and evaporator now operate at a high pressure and the condenser and generator at a low pressure. The Indus3Es system can produce a high-temperature reusable heat source, with a temperature higher than that of the low-grade waste heat, lifting the temperature of the process stream from 65 ºC to 135 ºC. Drawing on knowledge of absorption chiller operation, project researchers demonstrated several innovations in the developed system. These include the implementation of two adiabatic absorption operation modes, motor-less purge system for undesirable non-condensable gases and novel automatic control based on characteristic equation.

Getting the technology to the commercial stage

“Tapping industrial waste heat could reduce fossil fuel demands and improve efficiency of countless processes,” notes Martinez-Urrutia. “Our AHT enables large energy efficiency increases in energy-intensive industries – especially in the chemical and pharmaceutical, pulp and paper, food and beverage, and refinery sectors.” The first monitoring of the system operation showed promising results besides primary energy savings and CO2 emissions reduction. “The payback period of the 200 kW system proved to be concretely less than 10 years, which is a very positive value for a first 200 kW capacity level prototype. According to our estimations, a ready-to-market equipment investment would be recovered in about 6 years,” adds Martinez-Urrutia. Researchers have now the objective of developing systems able to work at even bigger scales. Martinez-Urrutia concludes that “the payback period would be reduced to 2 years with an AHT of 1 MW”. Achieving higher capacities would lead to a tremendous upsurge in the use of such an AHT in energy-intensive industries.