Helping the packaging industry switch from plastic to paper

Plastic is a cheap, durable material that is used widely in many different industries. Yet plastics are having increasing impacts on the environment, particularly in the world’s oceans, where millions of tonnes of plastic litter end up each year. As a result, Europe is trying to cut down on plastic use in certain industries, such as packaging. Plastic packaging has long been used as a durable material in the packaging industry. E-commerce is booming, which is expected to continuously boost demand. Yet the industry is now trying to become greener, using more ecologically friendly materials such as natural fibre and paper. It’s predicted that in the next 5 years, paper packaging in the EU will increase from 2 872 000 tonnes per year to more than 4 222 000 tonnes. One EU-supported project is hoping to help the transformation along. PAPER SOLUTIONS, a project run by Italian machinery firm Sitma(opens in new window), has created sophisticated technology that allows producers to retrofit plastic packaging machines, to create packaging using natural fibres, and specifically paper. PAPER SOLUTIONS technology is based on the installation of an ad hoc modular kit, which can perfectly integrate with pre-existing machines. It can work with plastic film, and also with new concept machines specially designed to work with paper. “Our commitment is to reduce eco-sustainable packaging costs, so they are as competitive as possible with plastic, making the eco-conversion of packaging automation increasingly affordable and more convenient,” says Fabrizio Della Casa(opens in new window), chief operating officer at Sitma.

Innovative solution

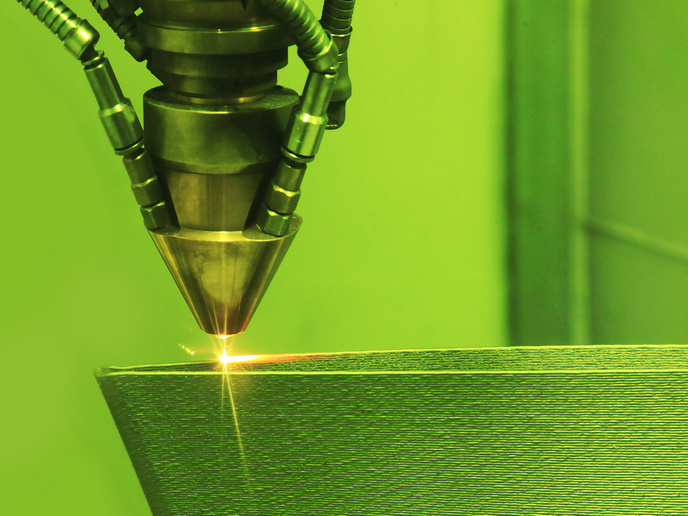

The system involves a combination of three elements: an unwinder(opens in new window) for paper reels, with an independent control system; a paper folding and conformation system, which guarantees the correct tension of the material and avoids damage; and a cutting and closing system, also specially designed to adequately protect the product and minimise waste. The system is equipped with on-board intelligence capable of managing different formats and tracking for individual packaging, useful for traceability and the idenfication of counterfeited raw material, and one-to-one interaction with the final consumer.

Advantage over competitors

The kit’s modular aspect represents its main advantage over competitors. And unlike other types of paper packaging machines on the market, which have long and bulky lines, the PAPER SOLUTIONS technology is specifically designed for smaller spaces and dimensions. “Everyone, even those who currently favour less sustainable solutions due to the costs and investments required to implement new technologies, will be able to easily switch to paper thanks to our solutions,” says Della Casa. This means that many products that today are individually packaged with plastic can be delivered in paper, lowering environmental impacts. “In addition, once the product heads to market, it will be possible to adapt the existing machine without having to invest in new automation, ensuring a fast payback,” he notes.

Heading to market

“We believe that, being able to access the funding this year, we will have the first industrialised solutions operational on the market in 2022,” Della Casa explains. PAPER SOLUTIONS units currently exist as prototypes, although they are already being used by some customers. “We would like to emphasise the importance of the SME fund for Sitma Machinery’s competitive development in reference to a fundamental company value: eco-sustainability(opens in new window).”