Novel catalytic reactions to make the world a greener, cleaner place

The SUSCAT (New Directions in Sustainable Catalysis by Metal Complexes) project, funded by the European Research Council (ERC) has its basis in several fields, including fundamental organometallic chemistry, coordination chemistry, organic synthesis, kinetics, spectroscopy, catalysis and density-functional theory (DFT) calculations that are based on quantum mechanical computation. “Overall, our key aims in SUSCAT were to discover and then develop novel, sustainable and environmentally benign catalytic reactions,” begins David Milstein, principle investigator of the project, professor and the Israel Matz Professional Chair of Organic Chemistry at the Weizmann Institute of Science. “Such reactions are useful for ‘green’ organic synthesis methodology which generates no waste and uses sustainable substrates, as well as the development of liquid organic hydrogen carrier (LOHC) systems.”

A flurry of catalyst successes

The catalyst development method used by SUSCAT is based on a mechanistic approach, employing both experimental and computational methods. Particularly significant for its work has been the use of pincer complexes as catalysts. In a nutshell, pincer complexes are a family of compounds that have had an important impact on the recent catalytic development of organic synthetic methods thanks to being stable and capable of versatile reactivity modes. SUSCAT has used these pincer complexes to pioneer several green and sustainable catalytic reactions useful for organic synthesis that can feasibly replace currently used polluting processes. “For example, one of our recently developed, unprecedented reactions is catalysed by a novel pincer manganese complex and leads to a family of compounds (acrylonitrile derivatives) that are valuable intermediates in the organic synthesis of a variety of products such as dyes, herbicides, fragrances, pharmaceuticals and natural products,” says Milstein. “Traditional methods of generating these products create harmful waste and so our new method is truly greener and better for the environment.” Another example of SUSCAT’s successes in green catalytic reactions includes a waste-free, one-step direct synthesis of amides (crucial for the pharma industry but traditional amide synthesis generates copious waste) and, as a happy consequence, the production of valuable hydrogen gas. A third, and very environmentally significant, example of a reaction accomplished by SUSCAT is the unprecedented hydrogenative depolymerisation of widely used, robust Nylons to form amino alcohols, efficiently catalysed by a ruthenium pincer complex. “Nylons are widely used and are non-biodegradable, which has increased both land and ocean pollution, posing a severe ecosystem threat,” Milstein comments. “This is why our accomplishment is so significant as the amino alcohols can be polymerised back to Nylons of similar molecular weight, thus providing a green and sustainable closed loop cycle for recycling Nylon waste.”

The hydrogen connection

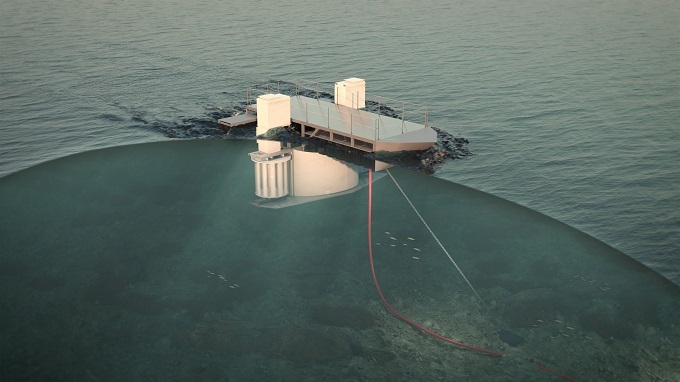

SUSCAT has also been at the forefront of developing a new LOHC system to safely and sustainably store hydrogen that can be used as a green energy carrier. “Hydrogen is considered an attractive energy vector due to its high gravimetric energy capacity, and the fact that it generates only water upon combustion,” explains Milstein. “However, its volumetric energy capacity is very low, requiring its storage (e.g. in cars) at very high pressure if in a gas state or as a liquid at a very low temperature (-253 °C) – both of which cost considerable energy investment and could be potentially dangerous. Using LOHC systems can avoid these problems.” The SUSCAT solution is founded on the fact that many of the project’s reactions generate or consume hydrogen gas and as a natural next step, they developed a LOHC system for hydrogen storage. “The theoretical hydrogen capacity of this system is 6.5 wt%, higher than the United States Department of Energy’s target for on-board hydrogen storage for light-duty vehicles, which is 5.5 wt%,” Milstein continues. “Whilst our LOHC system does require further development, we believe that it has the potential to be a top LOHC system, considering it’s a cheap, abundant sustainable hydrogen carrier, its use of a single catalyst, its mild operational conditions and its compatibility with existing infrastructure at petrol stations.” Looking to the future, Milstein and his team plan to continue their work on new catalytic reactions for green synthesis and hydrogen, possibly in collaboration with industrial partners. “What I’m most proud of in terms of SUSCAT is that we have hopefully made some contribution to the development of a truly greener world,” Milstein concludes.